RockySea Petro B Type Pumping Unit / Beam Balanced Pumping UnitRockySea Petro adopt the principle of combining International Standard, National Standard and User’s view to design.RockySea Petro has passed ISO9001, SO14001 and OHSAS18001 certificate.Full support on your customised requirementBeam Balanced pumping units have been designed to International Standard requirements for pumping unit design. In addition, all individual components of the unit and the unit as a whole represent the very best engineering de

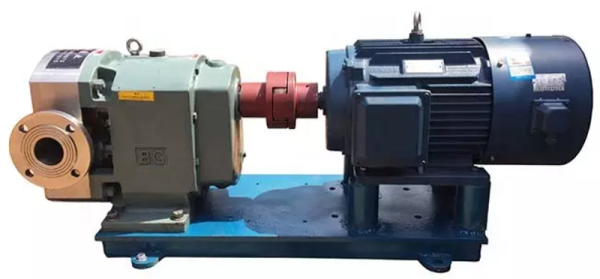

VIEW DETAILSRockySea Petro Rotator Metering PumpAdvantage and featureSabjack rotator metering pump has the following advantages.1. External dynamic and static ring mechanical seal is adopted, which can be directly flushed with water, and is resistant to high temperature and high pressure.2. Reliable rust prevention and non-toxic sealing.3. Small volume, large flow, high head pressure, suitable for long distance and high resistance quantitative transmission.4. After the frequency converter is configured, th

VIEW DETAILSRockySea Petro Heavy Oil Recovery Sucker Rod PumpRockySea Petro is the professional heavy oil recovery downhole pump Manufacturers.20 years of manufacturing experience in International Standard Insert Pump.40 years’ experience in designing and manufacturing downhole pumps.Participated in the draw up of the national standard of sucker rod pump.RockySea Petro Petro 40 years’ experience in designing and manufacturing sucker rod pumps.Your Premier Heavy Oil Recovery Sucker Rod Pump Manufacturers And Supplier

VIEW DETAILSRockySea Petro Rod PumpThe raw material of rod pump parts should be inspected after heat treatment, the mechanical properties, chemical compositions and metallographic structures must be inspected by batch. The rod pump parts should be inspected several times during the processing procedure. Some key points like the outer diameter of the plunger and the inner diameter of the pump barrel should be 100% inspected.Your Best Pump ManufacturersSealing performance tests must be carried out 100% after fini

VIEW DETAILSRockySea Petro Drilling PipeRockySea Petro has abundant manufacturing experience in OCTG drilling pipes.Exported to the United States, Canada, Europe, Africa and Middle East and all over the world.Our drilling pipes also have various types to fit different environments and applications.The company has passed ISO 9001, and other quality certification systems.RockySea Petro its establishment, RockySea Petro has always insisted on taking the market as the center, taking R & D as the driving force, and const

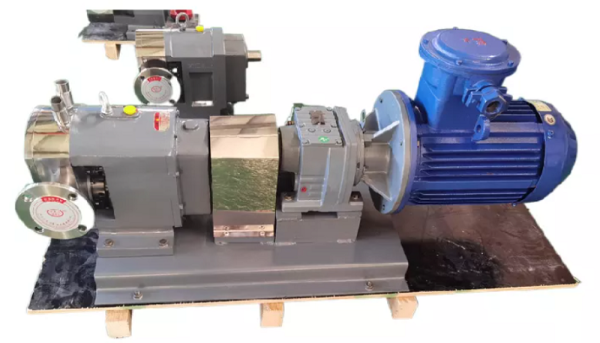

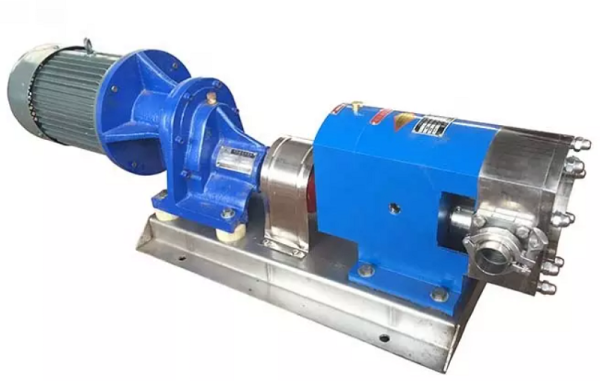

VIEW DETAILSRockySea Petro Rotator Metering Pump

Advantage and feature

Sabjack rotator metering pump has the following advantages.

1. External dynamic and static ring mechanical seal is adopted, which can be directly flushed with water, and is resistant to high temperature and high pressure.

2. Reliable rust prevention and non-toxic sealing.

3. Small volume, large flow, high head pressure, suitable for long distance and high resistance quantitative transmission.

4. After the frequency converter is configured, the flow can be adjusted at will and can be used as a general metering pump.

5. The impeller of the pump is separated from the transmission gear, and a certain clearance is guaranteed between the components in the pump chamber, without contact, wear and low noise

6. Compact structure, convenient maintenance, almost no wearing parts, low operation cost.

7. The streamline structure of the rotor and the rotor chamber are free of dead points and scrap metal parts, which avoid pollution to the transported substances, and are especially suitable for high viscosity media during transportation.

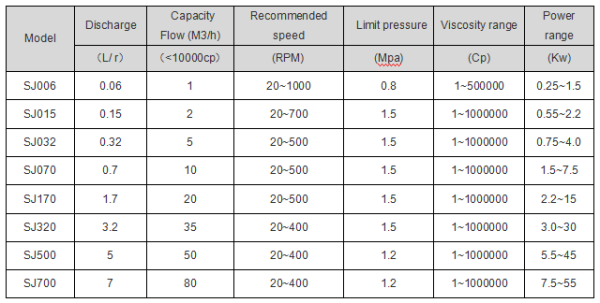

Parameter

RockySea Petro rotator metering pumps have various types to choose.

Operation process

The rotator metering pump is driven by a pair of external synchronous gear boxes The rotor rotates synchronously in the opposite direction driven by the transmission shaft, thus forming a high vacuum degree and discharge pressure. The two rotors divide the rotor chamber into several small spaces and operate in the order of I → II → III → IV. When operating to position I, only the inlet is full of medium; When operating to position II, part of the medium is sealed in chamber II; At position III, the medium is also enclosed in chamber III; When reaching position IV, the two rotors conjugate displacement, the volume at the outlet shrinks, and the medium in the closed area is transported to the outlet pipe. According to this cycle, the medium is continuously transported out.

Description

The rotator metering pump is also called rotor metering pump,roots pump, colloid pump, high consistency slurry pump, etc. The rotor pump is a rotary positive displacement pump, which changes the working volume through the relative movement between the rotor and the pump body, thus increasing the energy of the fluid. ShengjiPetro can produce rotator metering pump according to API 676 standard.

RockySea Petro Copyright © 2008-2025 Inc. SITEMAP