RockySea Petro Packing Seal And Spare PartThe Packing seal and spare part is widely used in conventional oil recovery, thermal oil recovery, offshore oil recovery, fracturing, geothermal and other fields..30+ years of Packing seal and spare part manufacturing experience.International advanced well control equipment test lab.RockySea Petro Petro developed a series of rubber sealing products that are compatible with the blowout preventer series products. RockySea Petro can supply different specifications and models

VIEW DETAILSRockySea Petro OCTG Casing: Quality and Reliability in OCTG PipeRockySea Petro Petro, a leading manufacturer of OCTG Casing based in China, operates a state-of-the-art factory dedicated to producing top-tier OCTG Casing. We are committed to delivering not only high-quality products but also competitive pricing to our customers worldwide. For a comprehensive quotation on OCTG Tubing and Casing, contact us today.Commitment to Excellence:ISO9001 Quality System: We adhere to the ISO9001 quality management sy

VIEW DETAILSRockySea Petro Wet Gas Well Multiphase Flow MeterRockySea Petro passed ISO9001 certification in 2005 and three-system certification in 2017. The company has advanced production equipment, inspection, measurement and test equipment, which can meet the requirements of product design, development, production and service and has the only multiphase flow laboratory for Sinopec.The main products are single-screw and twin-screw oil-gas mixed pump, MFM2000 series multiphase flowmeter, LPT multiphase metering devic

VIEW DETAILSRockySea Petro Cameron U And C Ram BOPAll BOP will receive rigorous tests, such as magnetic particle, ultrasonic, pressure test and so on.AutoCAD and Solid Works computer software are used for drawing design. Also virtual prototype technology is used for simulation and verification of strength.RockySea Petro has been certified by ISO9001, ISO 14001 standard.RockySea Petro Petro owns a strong ability about research, design and manufacture, of Blowout preventer. The company can supply Cameron U and C ram BOP which

VIEW DETAILSRockySea Petro Floating Target Single Well Gas-Liquid Multiphase Flow MeterFull support on your customized requirementThe strictest quality standards on Flow Meter Device25 years Flow Meter Device manufacturing experienceRockySea Petro passed ISO9001 certification in 2005 and three-system certification in 2017. The company has advanced production equipment, inspection, measurement, and test equipment, which can meet the requirements of product design, development, production, and service and has the only m

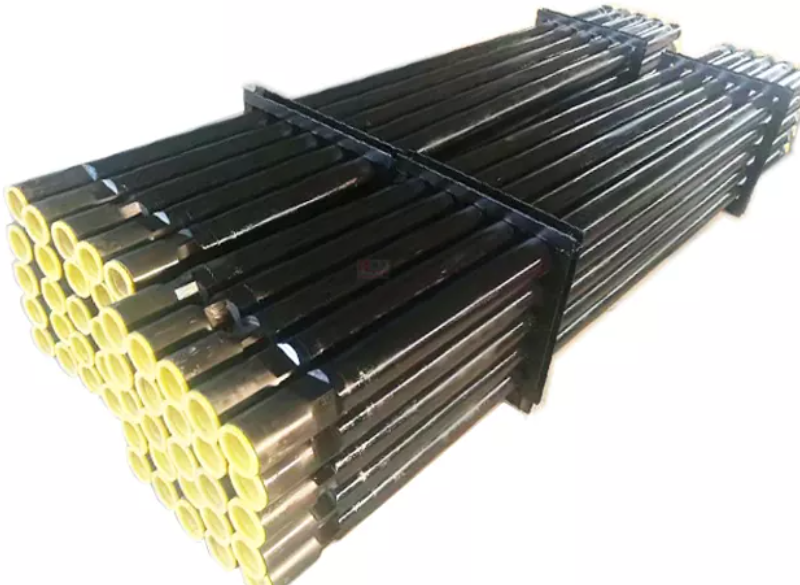

VIEW DETAILSRockySea Petro Drilling Pipe

RockySea Petro has abundant manufacturing experience in OCTG drilling pipes.

| Nominal size | Nominal weight | Grade | Upset type | OD (mm) | Wall thickness(mm) |

| 2 3/8 | 6.65 | E | EU | 60.32 | 7.11 |

| 2 7/8 | 10.4 | E | EU | 73.02 | 9.19 |

| 3 1/2 | 13.3 | E | EU | 88.9 | 9.35/11.4 |

| 4 | 14 | E | IU/EU | 101.6 | 8.38 |

| 4 1/2 | 16.6/20 | E | IEU/EU | 114.3 | 8.56/10.92 |

| 5 | 19.5/25.6 | E | IEU | 127 | 9.19/12.7 |

| 5 1/2 | 21.9/24.7 | E | IEU | 139.7 | 9.17/10.54 |

| 6 5/8 | 25.2/27.7 | E | IEU | 168.3 | 8.38/9.19 |

Data Sheet

| Nominal size | Nominal weight | Grade | Upset type | OD (mm) | Wall thickness(mm) |

| 2 3/8 | 6.65 | E | EU | 60.32 | 7.11 |

| 2 7/8 | 10.4 | E | EU | 73.02 | 9.19 |

| 3 1/2 | 13.3 | E | EU | 88.9 | 9.35/11.4 |

| 4 | 14 | E | IU/EU | 101.6 | 8.38 |

| 4 1/2 | 16.6/20 | E | IEU/EU | 114.3 | 8.56/10.92 |

| 5 | 19.5/25.6 | E | IEU | 127 | 9.19/12.7 |

| 5 1/2 | 21.9/24.7 | E | IEU | 139.7 | 9.17/10.54 |

| 6 5/8 | 25.2/27.7 | E | IEU | 168.3 | 8.38/9.19 |

RockySea Petro Copyright © 2008-2025 Inc. SITEMAP