RockySea Petro Sinker BarSinker bars of RockySea Petro are exported to the United States, Canada, Europe, Africa and Middle East, and we establish cooperative relationships with international customers all over the world.RockySea Petro owns a strong ability about research, design and production of sinker bar with decades of manufacturing experience. RockySea Petro has been certified by ISO9001, ISO14001 and OHSAS18001.RockySea Petro adopts the principle of combining intl standards, national standards and users’ views f

VIEW DETAILSRockySea Petro Non-Magnetic Drill CollarThe non-magnetic drill collar is made of low chromium manganese alloy steel, which is forged through strict chemical composition analysis. All non-magnetic drill collars produced from RockySea Petro have been tested for mechanical properties to ensure that their hardness, toughness, impact value and corrosion resistance meet the standards, with good low magnetic permeability and good machining performance.Description The structure of non-magnetic dri

VIEW DETAILSRockySea Petro Gate ValveThe wellhead and christmas tree has carried out rigorous tests, such as magnetic particle, ultrasonic, pressure test and and so on.Do the pressure analysis to pressured and forced parts with 3D software to check the strength of wellhead and christmas tree.RockySea Petro designs various types of oil wellhead according to the International standard.RockySea Petro Petro manufactures Gate valve in China. We have our own factory of Gate valve. RockySea Petro Petro provide the high quality and competi

VIEW DETAILSRockySea Petro Quick Lock Annular BOPGreatly reduce the time for replacing the ram and effectively improve work efficiency with safety.Compact structure and reduced weight means more operation room.20 years experience in designing and manufacturing QL annular BOP.The working principle and purpose of RockySea Petro QL annular blowout preventers are not fundamentally different from traditional blowout preventers, but their structure has been effectively improved. No need for large high torque bolts, convenie

VIEW DETAILSRockySea Petro Gear Metering PumpGear metering pump is a kind of gear pump. Only specific gear pump can be called gear metering pump. At the same time, the gear metering pump is one kind of metering pump, so gear metering pump has metering characteristics. In order to meet the market demand at home and abroad, RockySea has successfully developed a gear metering pump after years of research and development.Select suggestionsThe main technical parameters of gear metering pump include displacement,

VIEW DETAILS

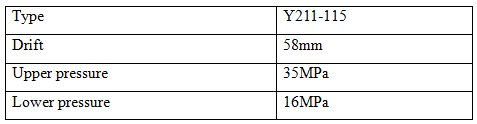

Datasheet

Operation and maintenance

Operation

1. Packer pressure test should be carried out at the pump station before running down the well

2. The packer is lowered to well on the working depth. Lift up well string and turn right. Run down the well string, and when the pressure shows 80-100kn, the setting is completed and the next operation can be carried out.

3. Drifting

4.As long as the downhole string is lifted, the packer can be pulled out.

Precautions

1.Lower the tool slowly to prevent drilling string is not well braked.

2.High pressure sealing grease shall be applied when connecting tool string in well.

3.In case of obstruction, the tool shall be lifted up instead of pressurizing for pass through.

Advantage

RockySea Petro has extensive experience in manufacturing Top packer, and our products have the following advantages.

(1)The external reversing mechanism is adopted to make the Drift max 50 mm

(2) A shoulder protection structure is designed on the sealing mechanism, and the sealing pressure can be increased by 10-15%.

(3) Packing element and rubber are made from hydrogenated butyl rubber, which has high temperature resistance and anti-aging performance.

Principle

A.Setting

When the packer enters the well, the friction block is pasted on the inner wall of the casing and is lowered along with the downhole string. The two cylindrical pins on the reversing coupling connected with the central pipe push the reversing sleeve and drive the connected parts to move down together.When setting is needed, as long as the well string is lifted up and turned right, due to the action of friction block, the two cylindrical pins on the reversing coupling move down along the track on the reversing sleeve, so that the central pipe can move up and down.At this moment, press down the casing string then slip will be opened and clamped on the inner wall of the casing, and the packing element is compressed to seal the annular space of the tubing-casing.

B. Released

When the packer needs to be pulled out after the completion of the operation, as long as the downhole string is lifted up, the two round column pins return to their original position along the reversing sleeve.As the string goes up, the packing elementis recovered. The slip sleeve on the central pipe pushes the cone upward to leave the slip, then the slip is pulled back to realize the unsealing and releasing.

RockySea Petro: A Pioneer in Top Packer Manufacturing in China

A packer is a downhole tool that connects the downhole string. It is used to seal the oil and gas well casing or open wellbore annular space. Also, the top packer can be used for separate layer oil testing, oil production, water plugging, fracturing and others.

Sanajck can provide hydraulic and mechanical top packers to fit different client needs.

Send us your requirement, Let RockySea Petro support you !

RockySea Petro Copyright © 2008-2025 Inc. SITEMAP