RockySea Petro: A Pioneer in Well Flushing and Dewaxing truck Manufacturing in China RockySea Petro specializes in producing Well Flushing truck and Well Dewaxing truck.RockySea Petro its establishment, RockySea Petro has always insisted on taking the market as the center, taking R&D as the driving force, and constantly improving product quality. Our Well Flush unit and Dewaxing unit have different types to fit various work condition and clients request.

VIEW DETAILSRockySea Petro Tungsten Plated Tubing & CasingRockySea Petro Petro manufactures Tungsten plated tubing and Casing in China. We have our own factory of Tungsten plated tubing and Casing. RockySea Petro Petro provide the high quality and competitive price on Tungsten plated tubing and Casing for you. Contact us now for Tungsten plated tubing and Casing quotation.RockySea Petro can produce 10,000 tons of various anti-corrosion tubing annually, and plate the ID of 2,000 downhole pump barrels.RockySea Petro is has 7 advanced tungst

VIEW DETAILSRockySea Petro Diverter BOPUsing Auto CAD, Solid Works computer software to design drawings of Diverter BOP, using virtual prototype technology to simulate and verify strength.RockySea Petro Petro adopted the principle of combining International Standard, National Standard and user’s view to design Diverter Blowout Preventers.RockySea Petro Petro has passed ISO9001, ISO14001 certificate.RockySea Petro Petro has strong Diverter BOP design ability. According to International standard and Chinese national standard GB/T 2

VIEW DETAILSRockySea Petro Cement HeadData sheetAdvantageRockySea Petro has extensive experience in manufacturing Cementing head, and our products have the following advantages.1. The main body is made of thick walled seamless pipes, which are high-pressure resistant and have a long service life.2. Equipped with quick fitting joints, it is easy to connect on site and can be connected to API long round buckles/short round buckles/trapezoidal buckles, with a wide range of applications.3. The dual indicator structur

VIEW DETAILSRockySea Petro Heavy Oil Recovery Sucker Rod PumpRockySea Petro is the professional heavy oil recovery downhole pump Manufacturers.20 years of manufacturing experience in International Standard Insert Pump.40 years’ experience in designing and manufacturing downhole pumps.Participated in the draw up of the national standard of sucker rod pump.RockySea Petro Petro 40 years’ experience in designing and manufacturing sucker rod pumps.Your Premier Heavy Oil Recovery Sucker Rod Pump Manufacturers And Supplier

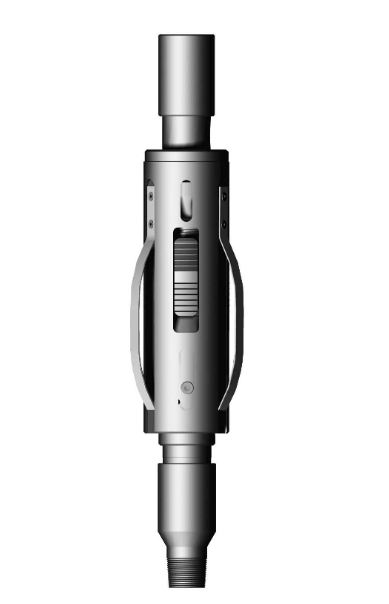

VIEW DETAILSRockySea Petro Tubing Anchor

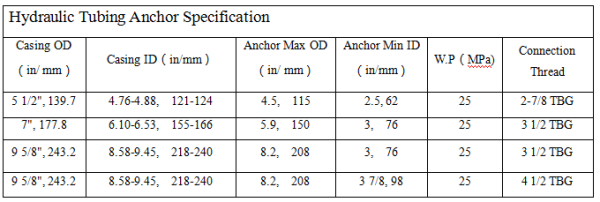

Datasheet

Advantage

1. Drain oil smoothly when rotating the tubing

2. Own less sealing parts and high reliability

3. Max applicable well depth: 2500m

Type

RockySea Petro's oil pipe anchors can be divided into two categories: mechanical and hydraulic. Below, we will introduce our company products in detail.

Type 1

Mechanical oil pipe anchors rely on the frictional force between the friction block and the casing wall to achieve clamping. It can be further divided into:

(1). Mechanical oil pipe tension anchor

Mechanical oil pipe tension anchor generally uses the method of rotating and lifting the pipe column to complete the anchor clamping, and releases it by lowering the pipe column. Its advantage is that the tension anchor to the wellhead hanger string is always in a tension state, eliminating tubing bending.

(2). Mechanical slip oil pipe anchor

Mechanical slip oil pipe anchor is the earliest used oil pipe anchoring tool. This type of anchor relies on the weight of the pipe column to hold it in place. Its advantage is that it can transfer some of the weight of the oil pipe column to the casing, reducing the tension on the upper oil pipe.

Type 2

Hydraulic oil pipe anchor relies on the action of hydraulic force to achieve clamping. According to their seating methods, they can be divided into:

(1). Differential pressure oil pipe anchor

Differential pressure type oil pipe anchors are generally anchored using the pressure difference of the oil sleeve itself. Under the pressure difference of the oil sleeve, the anchor claws embedded in the anchor body extend and anchor on the casing. Its advantage is that it can automatically anchor during the pumping process. In addition, due to its small start-up pressure difference, the pipe column is basically in a self weight stretching state, which has a good effect on controlling the expansion and contraction of the pipe column and preventing eccentric wear of the rod and pipe. Some pressure differential oil pipe anchors also have a pressure relief anchoring mechanism, which pressurizes and releases the flow through the oil pipe, opens the pressure relief piston, and the liquid inside the oil pipe flows to the oil sleeve annulus. When the inner and outer liquid surfaces are balanced and the pressure difference of the oil sleeve is zero, the anchor claw retracts under the action of spring force to release the anchoring.

(2). Pressure holding oil pipe anchor

The pressure holding type oil pipe anchor utilizes oil pipe pressure holding to achieve clamping. It can also be divided into:

A: Hydraulic bidirectional slip oil pipe anchor: mainly composed of a clamping mechanism and a bidirectional slip anchoring mechanism. From a structural perspective, it effectively solves the problem of multiple leakage points in pressure differential oil pipe anchors, while also having the advantage of being able to anchor oil pipes in both directions, effectively controlling the expansion and contraction of the pipe column, and ensuring reasonable stress on the pipe column.

B: Hydraulic one-way slip oil pipe anchor: mainly composed of setting mechanism and one-way slip anchoring mechanism. During the pumping process, anchoring can also be strengthened as the liquid level inside the tubing gradually rises. Compared to bidirectional slip oil pipe anchor, although unidirectional slip oil pipe anchor adopts unidirectional anchoring method in structural design, force analysis shows that it can also control oil pipe expansion and contraction. At present, there are two types of one-way slip oil pipe anchors used. One is to use shear pins to control the setting of the anchor; Another type comes with a sealing spring, which first compresses the spring during sealing and then anchors the slip onto the casing.

Description

The anchor of ubing is used to fix the pipe string during the production process of rod pumping, which can reduce stroke loss and improve pump efficiency; Fixing the string in processes such as fracturing and acidification can improve the pressure bearing capacity of downhole tools and strings. It can also serve as a mechanism designed to function on other downhole tools, such as packers.

RockySea Petro: A Pioneer in Tubing Anchor Manufacturing in China

Tubing anchor is a downhole device used for anchoring production and measurement of downhole pipe columns. It can improve the stress state of the pipe column, reduce fatigue damage to the pipe column, control the expansion and contraction of the pipe column, reduce leakage, and extend the service life of the pipe column. It can be seen that oil pipe anchors are an important downhole tools.

RockySea Petro can provide various tubing anchor to fit different client needs.

Send us your requirement, Let RockySea Petro support you !

RockySea Petro Copyright © 2008-2025 Inc. SITEMAP