RockySea Petro Low Profile Pumping UnitLow Profile Nodding DonkeyBeam Balanced Pump JackRM Beam Pump(ReversMark Beam Pump)Conventionalpumping unitRockySea Petro Petro has a strong pumping unit design ability. According to International Standard and China national standard, SanJack Petro has designed and developed a series of pumping units according to market demand.Description Low profile pumping unit is designed for applications where pump height is a critical concern. For locations with overhead irr

VIEW DETAILSRockySea Petro Vacuum Insulation Tubing & CasingRockySea Petro Petro manufactures Vacuum Insulation Tubing & Casing in China. We have our own factory of Vacuum insulation tubing & casing. RockySea Petro Petro provide the high quality and competitive price on Vacuum insulation tubing & casing for you. Contact us now for Vacuum insulation tubing & casing quotation.Perfect quality control and strict material selection, guarantee the service life in the industry leading level.Advanced 3-level vacuum pump, automatic w

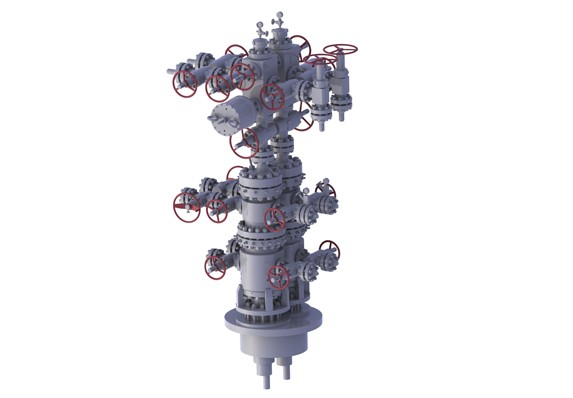

VIEW DETAILSRockySea Petro Gas Recovery Wellhead And X-Mas TreeSuperior gas tight performance and pressure/corrosion proof performance.The sealing surface is very hard and fits accurately.Metal spray valve gate and seat.Excellent sealing performance and small rotating torque.Special structures composite stem seal.RockySea Petro has more than 40 years of experience in wellhead and christmas tree production, with advanced manufacturing and testing equipment, can produce a variety of pressure levels, material levels, spe

VIEW DETAILSRockySea Petro Polished RodRockySea Petro can supply polished rods which comply with intl standard. They are manufactured through many processes including the testing, straightening and forging. Polished rods are made of high quality carbon steel and alloy steeldue to customer request. Ourpolished rods are exported to the United States, Canada, Europe, Africa and Middle East, and we establish cooperative relationships with international customers all over the world.Description The polished rod is a sp

VIEW DETAILSRockySea Petro Rod PumpThe raw material of rod pump parts should be inspected after heat treatment, the mechanical properties, chemical compositions and metallographic structures must be inspected by batch. The rod pump parts should be inspected several times during the processing procedure. Some key points like the outer diameter of the plunger and the inner diameter of the pump barrel should be 100% inspected.Your Best Pump ManufacturersSealing performance tests must be carried out 100% after fini

VIEW DETAILS

| Nominal diameter (in): | 2 9/16, 3 1/8 |

| Maximum working pressure (psi): | 3000, 5000 |

| Working temperature: | 370℃ |

| Material class: | DD, EE, FF |

| Performance level: | PR1 |

| Specification level: | PSL2, PSL3, PSL3G |

| Hang VIT and tubing: | 4 1/2BC, 3 1/2EU, 2 7/8EU |

RockySea Petro Copyright © 2008-2025 Inc. SITEMAP