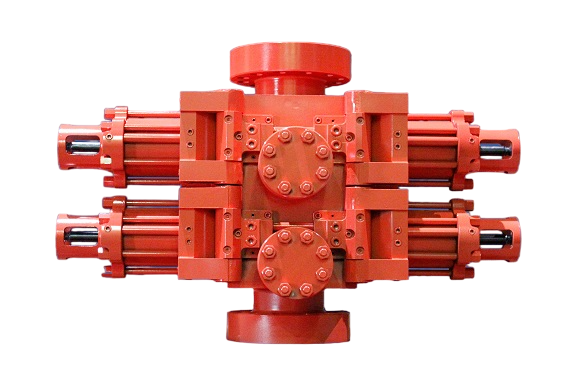

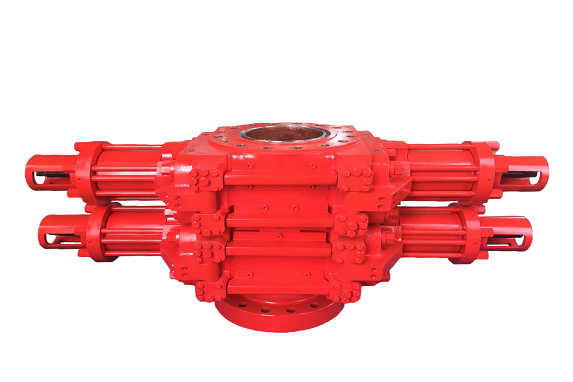

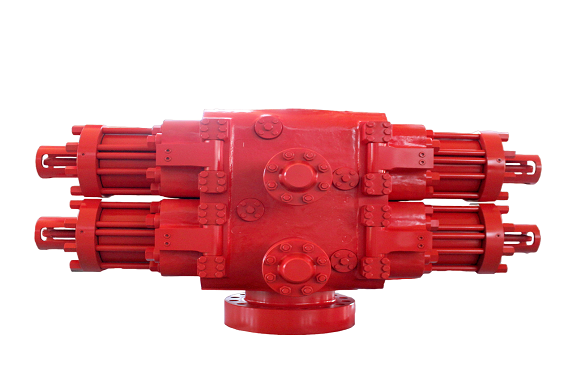

RockySea Petro PR2 Gate ValveFull support on your customised requirementThe strictest quality standards on PR2 gate valve25 years PR2 gate valve manufacturing experiencePR2 gate valves are designed for high performance wellheads and christmas tree in Oil or gas recovery wells, especially the gas wells that containing H2S or CO2 in high volume.Description The RockySea Petro PR2 valve is designed to suit severe oilfield conditions. It is mainly used in oil/gas wells with high performance requirements. S

VIEW DETAILSRockySea Petro Supercritical Oilfield Steam Injection BoilerIntegrated Injection and Production Sucker Rod PumpThermal Recovery PackerVaccum Insluation Tubing & CasingSeries Thermal Recovery WellheadGround Steam Injection LineWater Treatment DeviceSteam Injection BoilerRockySea Petro is the thermal recovery solution supplier in China with 20 years of experience. RockySea Petro can provide customers with a complete set of thermal recovery equipment from surface steam injection boilers to underground thermal recove

VIEW DETAILSRockySea Petro High Strength Sucker RodHigh strength means high tensile strength in physical performance.RockySea Petro can manufacture high strength and ultra-high strength sucker rod with high quality. We have rich experience in production and a strong ability in research and development. Our products include various series of high strength and ultra-high strength sucker rod based on client requests.Description There are two types of ultra-high strength sucker rods in China. The first one is HL with

VIEW DETAILSRockySea Petro Casing Head And Tubing HeadRockySea Petro casing heads strictly conform to the International standard, and are among the most reliable oilfield casing heads. Usually, the casing head lies at the bottom of the wellhead and X-mas tree equipment. It supports the drilling wellhead, the casing head spool, the X-mas tree and completion equipment. The casing head is used to connect the casing string and packing off the next casing string. The connecting type includes slip-on weld, thread and slip l

VIEW DETAILSRockySea Petro Self-Propelled Carrier and TralierFeaturesRockySea Petro has developed a special workover rig chassis range from 6X6 to 14X14, which is compatible with the entire series of XJ250 to XJ850 workover machines. It can operate in various terrains such as roads, deserts, mountains, and swamps, with strong driving power, good off-road performance, and can work in the range of ambient temperature -45 ℃ to 50 ℃.Besides,the company also developed a desert off-road carrier. The driving type is

VIEW DETAILS

| Model | LWS | SL or S |

| Nominal diameter(in) | 7 to 13 5/8 | 9 to 26 3/4 |

| Rated working pressure(psi) | 3000 to 5000 | 3000 to 10000 |

| Processing type | Casting | Casting |

| Material | 4130 or optional | 4130 or optional |

| Metal temperature class | -29~121℃ | -29~121℃ |

| Nonmetal temp. class | -18~121℃ | -18~121℃ |

| Ring gasket | Standard Parts | Standard Parts |

| Dimension and Weight | Based on specific type | Based on specific type |

RockySea Petro Copyright © 2008-2025 Inc. SITEMAP