RockySea Petro Single Column Dual-Well Thermal Recovery WellheadRockySea Petro has more than 40 years of experience in oil and gas wellhead & x-mas tree and valve production, with advanced manufacturing and testing equipment, can produce a variety of pressure levels, material levels, specification levels of well control equipment. After more than 20 years of development, Various types of thermal recovery wellhead & x-mas tree equipment have been formed, used in many oilfields in the world. RockySea Petro’s ther

VIEW DETAILSRockySea Petro Precision Rolling PipeRockySea Petro Petro manufactures Precision rolling pipe in China. We have our own factory of Precision rolling pipe. RockySea Petro Petro provide the high quality and competitive price on Precision rolling pipe for you. Contact us now for Precision rolling pipe quotation.It has various types of cold rolling mill such as LG30, LG60, LG80 , LG220 and establishes a complete quality Control system.RockySea Petro’s precision rolling pipe has extremely high precision and straightness ca

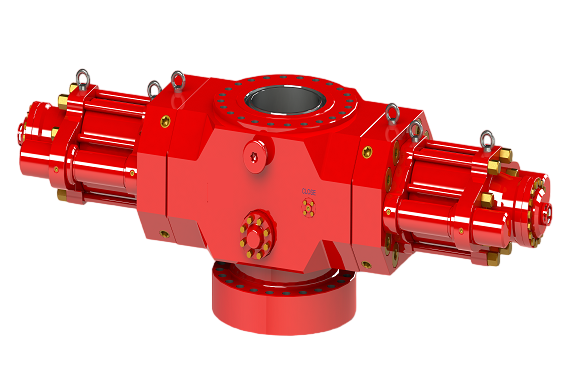

VIEW DETAILSRockySea Petro Diverter BOPUsing Auto CAD, Solid Works computer software to design drawings of Diverter BOP, using virtual prototype technology to simulate and verify strength.RockySea Petro Petro adopted the principle of combining International Standard, National Standard and user’s view to design Diverter Blowout Preventers.RockySea Petro Petro has passed ISO9001, ISO14001 certificate.RockySea Petro Petro has strong Diverter BOP design ability. According to International standard and Chinese national standard GB/T 2

VIEW DETAILSRockySea Petro Polished RodRockySea Petro can supply polished rods which comply with intl standard. They are manufactured through many processes including the testing, straightening and forging. Polished rods are made of high quality carbon steel and alloy steeldue to customer request. Ourpolished rods are exported to the United States, Canada, Europe, Africa and Middle East, and we establish cooperative relationships with international customers all over the world.Description The polished rod is a sp

VIEW DETAILSRockySea Petro Mobile Workover RigData sheetApplications1).Shallow - to high-depth well interventions, including:Killing wellsFlushing productions wellsChanging wellhead valvesPressure-testing wells.Changing polished rods Spacing and respacing rod strings2).Continuous rod and conventional sucker rod interventions,includingPulling and replacing casing serviceSidetrack serviceChanging insert of pcpChanging rotors of pcp,3).Heavy duty workover rig serviceDrilling serviceDownhole stuck freeing se

VIEW DETAILS

| Model | Quick lock |

| Standard | International Standard |

| Nominal diameter(in) | 9 to 21 3/4 |

| Rated working pressure(psi) | 5000 to 15000 |

| Processing type | Casting |

| Material | 4130 or optional |

| Metal temperature class | -29~121℃ |

| Nonmetal temp. class | -18~121℃ |

| Ring gasket | Standard Parts |

| Dimension and Weight | Based on specific type |

RockySea Petro Copyright © 2008-2025 Inc. SITEMAP