RockySea Petro Casing Head And Tubing HeadRockySea Petro casing heads strictly conform to the International standard, and are among the most reliable oilfield casing heads. Usually, the casing head lies at the bottom of the wellhead and X-mas tree equipment. It supports the drilling wellhead, the casing head spool, the X-mas tree and completion equipment. The casing head is used to connect the casing string and packing off the next casing string. The connecting type includes slip-on weld, thread and slip l

VIEW DETAILSRockySea Petro Top PackerDatasheetOperation and maintenanceOperation1. Packer pressure test should be carried out at the pump station before running down the well2. The packer is lowered to well on the working depth. Lift up well string and turn right. Run down the well string, and when the pressure shows 80-100kn, the setting is completed and the next operation can be carried out.3. Drifting4.As long as the downhole string is lifted, the packer can be pulled out.Precautions1.Lower the tool slowly

VIEW DETAILSRockySea Petro Sucker Rod CouplingThe sucker rod couplings are used for connecting sucker rods, polished rods and sinker bars. Material of the couplings is high quality carbon steel or alloy steel, which are conform to and exceed the requirements of intl standards.Description According to surface of suck rod couplings, they can be divided into sucker rod couplings with smooth surface and sucker rod couplings with wrench square.Sucker rod couplings with wrench square.Sucker rod couplings with sm

VIEW DETAILSRockySea Petro Diverter BOPUsing Auto CAD, Solid Works computer software to design drawings of Diverter BOP, using virtual prototype technology to simulate and verify strength.RockySea Petro Petro adopted the principle of combining International Standard, National Standard and user’s view to design Diverter Blowout Preventers.RockySea Petro Petro has passed ISO9001, ISO14001 certificate.RockySea Petro Petro has strong Diverter BOP design ability. According to International standard and Chinese national standard GB/T 2

VIEW DETAILSSanajck Swabbing TruckData sheetFeature 1.The swabbing truck has the advantages of continuous and reliable operation, convenient parameter adjustment, high drainage efficiency, and simple handling and installation. It solves the problems of discontinuous swabbing and drainage operation, low drainage efficiency, and cumbersome equipment handling,compared with existing drainage technologies. 2.Through on-site testing, the feasibility and reliability of the on-site application of

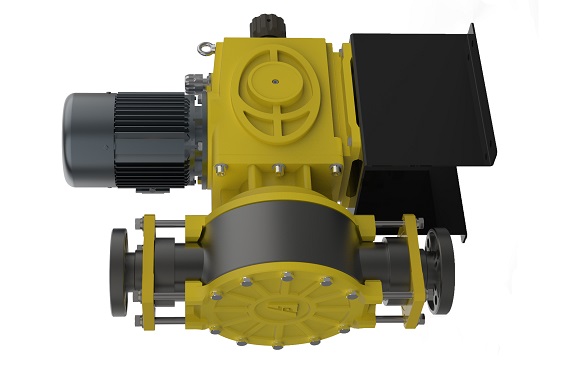

VIEW DETAILSRockySea Petro Pneumatic Diaphragm Metering Pump

Pneumatic diaphragm pump is a new type of conveying machinery, which is the most novel pump in China at present. Compressed air is used as the power source to pump out all kinds of corrosive liquids, liquids with particles, high viscosity, volatile, flammable and highly toxic liquids. The pneumatic diaphragm metering pump is a new product developed by RockySea in recent years and is used in various special occasions.

Application

1. Food Processing/Biological Hygiene/Pharmaceutical

2. Chemical Petroleum

3. Ceramic paint

4. Wastewater treatment

5. Chemical buildings/public facilities

6. Automotive Plating & Polishing

Feature

The Pneumatic diaphragm metering pump of RockySea has the following advantages.

1. Suitable for medium and high viscosity fluids.

2. Applicable to places with harsh environment, such as construction sites

3. In the treatment of hazardous and corrosive materials, the diaphragm pump can completely isolate the materials from the outside world.

4. Reliable and low cost pneumatic pump in flammable and explosive environment.

5. The pneumatic diaphragm pump is small in size and easy to move, does not need a foundation, occupies a very small area, and is simple and economical to install.

6. It can be used to transport and measure fluid with unstable chemical properties, such as photosensitive materials, flocculating liquid, etc.

Working principle

The pneumatic diaphragm metering pump is one kind of positive displacement pump whose volume changes due to the reciprocating deformation of the diaphragm. Its working principle is similar to that of a plunger pump

Two symmetrical working chambers of the pump are respectively equipped with an elastic diaphragm. The linkage links the two diaphragms together. After the compressed air enters the valve from the intake head of the pump, it pushes the diaphragms in the two working chambers to drive the two diaphragms connected by the linkage to move synchronously. At the same time, the gas in the other working chamber is discharged from the back of the diaphragm outside the pump.

Once the end of the journey is reached, the valve distribution mechanism automatically introduces compressed air into another working chamber to push the diaphragm to move in the opposite direction, thus forming a synchronous reciprocating motion of the two diaphragms. Each working chamber is equipped with two one-way ball valves. The reciprocating movement of the diaphragm changes the volume of the working chamber, forcing the two one-way ball valves to open and close alternately, thus continuously absorbing and discharging liquid.

RockySea Petro: A Pioneer in Pneumatic Diaphragm Metering Pump Manufacturing in China

Pneumatic diaphragm pump is a new type of conveying machinery, which is the most novel pump in China at present. Compressed air is used as the power source to pump out all kinds of corrosive liquids, liquids with particles, high viscosity, volatile, flammable and highly toxic liquids. The pneumatic diaphragm metering pump is a new product developed by RockySea in recent years and is used in various special occasions.

Send us your requirement, Let RockySea Petro support you !

RockySea Petro Copyright © 2008-2025 Inc. SITEMAP