RockySea Petro Flush by UnitData sheetApplicationsRSR of RockySea can efficiently and quickly complete various oilfield workover operations as the following: 1).Heavy duty workover serviceDrilling serviceDownhole stuck freeing serviceSealing and channeling serviceCasing shaping serviceCasing repair service2).Shallow- to high-depth well interventions, including:Killing wellsFlushing productions wellsChanging wellhead valvesPressure-testing wells.Changing polished rods Spacing and respac

VIEW DETAILSRockySea Petro Rotator Metering PumpAdvantage and featureSabjack rotator metering pump has the following advantages.1. External dynamic and static ring mechanical seal is adopted, which can be directly flushed with water, and is resistant to high temperature and high pressure.2. Reliable rust prevention and non-toxic sealing.3. Small volume, large flow, high head pressure, suitable for long distance and high resistance quantitative transmission.4. After the frequency converter is configured, th

VIEW DETAILSRockySea Petro Wet Gas Well Multiphase Flow MeterRockySea Petro passed ISO9001 certification in 2005 and three-system certification in 2017. The company has advanced production equipment, inspection, measurement and test equipment, which can meet the requirements of product design, development, production and service and has the only multiphase flow laboratory for Sinopec.The main products are single-screw and twin-screw oil-gas mixed pump, MFM2000 series multiphase flowmeter, LPT multiphase metering devic

VIEW DETAILSRockySea Petro Superheated Steam Injection BoilerSupercritical Oilfield Steam Injection BoilerDesulfurization and Denitrification Oilfield Steam BoilerProduced-water Oilfield Steam GeneratorSuperheated Oilfield Steam BoilerHigh-dryness Steam Injection BoilerOilfield steam injection boiler, also known as wet steam generator, is a special steam injection equipment for heavy oil recovery in oil fields. It uses the heat generated by the combustion of gas or fuel oil to heat and vaporize water, genera

VIEW DETAILSRockySea Petro Steam Injection And Oil Recovery WellheadGeothermal wellhead & x-mas treeBlowout preventer Steam Injection and Oil Recovery Integration wellhead & x-mas treeSteam injection and oil recovery dual tubing wellhead & x-mas treeSingle column dual-well thermal recovery wellhead & x-mas treeOnshore thermal recovery wellhead & x-mas treeConventional Steam injection and oil recovery wellhead & x-mas treeRockySea Petro has more than 40 years of experience in oil and gas wellhead & x-mas tree and valve

VIEW DETAILSRockySea Petro Casing Stop Ring

Datasheet

Use

When using the top thread stop ring, the following steps should be followed.

1. When using the fixed screw type, first insert the sleeve, then insert the screw and use a hammer to strike.

2. The conventional stop ring should be inserted into the sleeve first, and then the screw should be tightened with a wrench.

3. Snap on the locking ring, directly attach the locking ring to the sleeve, lock it with a pin, and then tap in the screw.

Type

The stop rings of RockySea can be classified into three types of structures: top screw, fixed screw, and buckle type.

1. The fixed screw type stop ring consists of a stop ring body, a pin, and a pin. The stop ring is hinged and consists of two semicircles, which are easy to fit on the sleev

2. The top screw stop ring is composed of a stop ring and an internal hexagonal screw, which is simple to use and easy to disassemble and assemble.

3. The buckle type be divided into hinge type and sliding sleeve type. Hinge buckle stop ring, directly buckle the stop ring onto the sleeve, insert the buckle ring into the tongue, and hammer the tongue in the opposite direction to secure it.

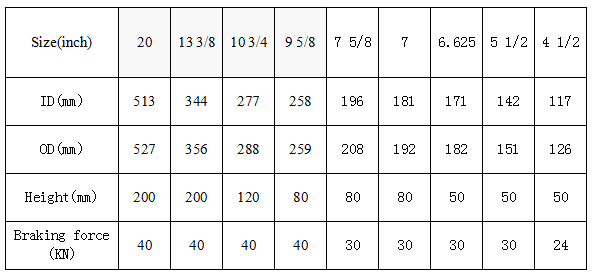

Our product sizes range from 4-1/2 "to 20" and can be machined according to customer requirements.

Description

The Casing stop ring is also called casing snap ring or retainer , can be installed at any position on the casing to limit the axial sliding of the centralizer or cement umbrella on the inner casing, ensuring that the centralizer or cement umbrella is in the design position.

RockySea Petro: A Pioneer in Casing Stop Ring Manufacturing in China

The Casing stop ring is also called casing snap ring or retainer , can be installed at any position on the casing to limit the axial sliding of the centralizer or cement umbrella on the inner casing, ensuring that the centralizer or cement umbrella is in the design position.

RockySea Petro can provide various casing snap rings to fit different client needs.

Send us your requirement, Let RockySea Petro support you !

RockySea Petro Copyright © 2008-2025 Inc. SITEMAP