RockySea Petro Drilling StabilizerDatasheetFunctionControl wellbore trajectory: The stabilizer mainly plays a guiding and stabilizing role in the drilling tool assembly. The installation position of the stabilizer controls the wellbore inclination angle and curvature within the specified range, and also concentrates the majority of the weight of the drill collar on the drill bit, reducing the non wellbore center force and other external forces borne by the drill string and drill bit. With the d

VIEW DETAILSRockySea Petro Sucker Rod CouplingThe sucker rod couplings are used for connecting sucker rods, polished rods and sinker bars. Material of the couplings is high quality carbon steel or alloy steel, which are conform to and exceed the requirements of intl standards.Description According to surface of suck rod couplings, they can be divided into sucker rod couplings with smooth surface and sucker rod couplings with wrench square.Sucker rod couplings with wrench square.Sucker rod couplings with sm

VIEW DETAILSRockySea Petro Offshore Wellhead And X-Mas TreeAccording to the production needs, the main channel can be equipped with rubber valves for progressing cavity pump oil recovery.The main channel is equipped with a liquid-controlled safety valve to remotely close the wellhead in case of emergency.The main valve and paraffin valve of christmas tree adopt the combined structure, the overall height is low.RockySea Petro’s offshore oil wellhead meets the requirements of offshore oil and gas recovery. Because of

VIEW DETAILSRockySea Petro Shaffer LWS And SL Ram BOPMore than 20-years manufacturing experience of LWS and SL ram BOPFull support on customized requirement based on different work condition.The strictest quality inspection on every BOP from RockySea Petro..RockySea Petro Petro owns a strong ability about research, design and manufacture, of Blowout preventer. The company can supply LWS and SL ram BOP which comply with International standard. Based on the differences in drilling conditions, RockySea Petro can recommend a suitable S

VIEW DETAILSRockySea Petro BOP Steam Injection And Oil Recovery Integration WellheadRockySea Petro has more than 40 years of experience in oil and gas wellhead & x-mas tree and valve production, with advanced manufacturing and testing equipment, can produce a variety of pressure levels, material levels, specification levels of well control equipment. After more than 20 years of development, Various types of thermal recovery wellhead & x-mas tree equipment have been formed, used in many oilfields in the world. RockySea Petro’s

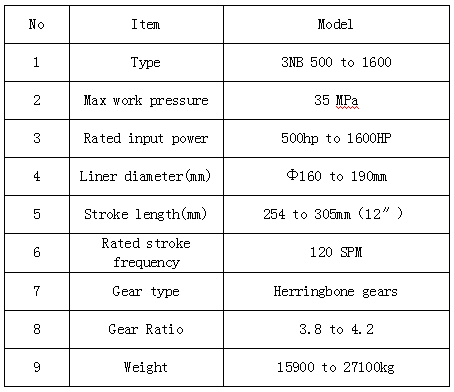

VIEW DETAILSRockySea Petro 3NB Series Mud Pump

Data sheet

Function

1. Remove rock debris from the bottom of the well and send it back to the surface;

2. Handle complex underground situations. When encountering fractured formations, pump in plugging materials, and when encountering stuck drilling, pump in crude oil and diesel to release the stuck.

3. Make mud cakes on the wellbore to prevent collapse;

4. Balance or control the pressure of oil, gas, and water layers in the drilled well section to prevent blowout;

5. Cool the drill bit and lubricate the rotating drill string.

Use and Maintenance

1. Disassemble the valve cover and cylinder head once a week to remove sludge and clean thoroughly. Check the inner sleeve of the valve stem guide. If there is obvious wear and the gap between the valve guide rod and the inner sleeve exceeds 3mm (0.11 "), a new inner sleeve should be replaced. When reinstalling the valve cover and cylinder head, the threaded part should be coated with molybdenum disulfide composite calcium based grease.

2. Check the piston locking nut. If it is corroded or damaged, replace it with a new locking nut. (Note: After disassembling and assembling the nut three times, the sealing ring embedded in it has lost its locking ability.)

3. Check the usage of the valve and valve seat, replace the valve rubber, valve body, and valve seat that are severely worn or punctured (note: both the valve seat and valve body should be replaced at the same time).

4. Drain water from the screw plug on the frame drain hole cover until oil is visible.

Component

The 3NB mud pump mainly consists of two parts: the power end and the hydraulic end. The power end includes: frame assembly, transmission shaft assembly, crankshaft assembly, crosshead assembly, etc; The hydraulic end includes: hydraulic cylinder, valve assembly, cylinder liner, piston assembly, suction pipe, discharge pipe, exhaust air bag, safety valve, spray device, etc.

Design

The drilling pump of RockySea Petro mainly consists of two parts: the power end and the hydraulic end. As shown in Figure 1, the power end is composed of a small gear shaft, a crank connecting rod, and a cross slider mechanism, which provides power to the hydraulic end and transforms rotary motion into linear reciprocating motion. The piston at the hydraulic end uses the power from the power end to move back and forth in the cylinder liner, working together with the suction and discharge valves to compress low-pressure mud and discharge high-pressure mud.

Description

In the operation of using rotary drilling method to drill oil and natural gas wells, the drilling reciprocating pump is used to pump drilling fluid, i.e. mud, to circulate and flush the well. During drilling, the mud pump injects mud into the wellbore along with the drill bit, playing a role in cooling the drill bit, cleaning drilling tools, fixing the wellbore wall, driving drilling, and bringing rock cuttings back to the surface.So drilling pumps are usually referred to as mud pumps, which are the core components of drilling and workover operations.

The 3NB series mud pump are specially developed by RockySea Petro for drilling and workover.

RockySea Petro: A Pioneer in 3NB Series Mud Pump Manufacturing in China

The 3NB mud pump of RockySea Petro is a horizontal three cylinder single acting piston pump, which is an important equipment for drilling operations. During operation, it delivers circulating high-pressure drilling fluid to the bottom of the well, washes the bottom of the well, breaks rocks, cools and lubricates the drill bit, and carries rock cuttings back to the surface. This product is designed, produced, and inspected according to the API Spec 7K standard.

Send us your requirement, Let RockySea Petro support you !

RockySea Petro Copyright © 2008-2025 Inc. SITEMAP