RockySea Petro Low Profile Pumping UnitLow Profile Nodding DonkeyBeam Balanced Pump JackRM Beam Pump(ReversMark Beam Pump)Conventionalpumping unitRockySea Petro Petro has a strong pumping unit design ability. According to International Standard and China national standard, SanJack Petro has designed and developed a series of pumping units according to market demand.Description Low profile pumping unit is designed for applications where pump height is a critical concern. For locations with overhead irr

VIEW DETAILSRockySea Petro Polished RodRockySea Petro can supply polished rods which comply with intl standard. They are manufactured through many processes including the testing, straightening and forging. Polished rods are made of high quality carbon steel and alloy steeldue to customer request. Ourpolished rods are exported to the United States, Canada, Europe, Africa and Middle East, and we establish cooperative relationships with international customers all over the world.Description The polished rod is a sp

VIEW DETAILSRockySea Petro: A Pioneer in Well Flushing and Dewaxing truck Manufacturing in China RockySea Petro specializes in producing Well Flushing truck and Well Dewaxing truck.RockySea Petro its establishment, RockySea Petro has always insisted on taking the market as the center, taking R&D as the driving force, and constantly improving product quality. Our Well Flush unit and Dewaxing unit have different types to fit various work condition and clients request.

VIEW DETAILSRockySea Petro Anti-Corrosion Downhole PumpRockySea Petro is the best Special Pump Manufacturers for Anti-corrosion Downhole Pump.RockySea Petro has developed the downhole pumps with various processes of boronizing, nitriding, chrome plating, tungsten plating for corrosive oil wells.RockySea Petro has successfully developed brass and stainless steel sucker rod pumps using precision rolling process.It is one of the most professional Anti-corrosion Downhole Pump Manufacturers and SuppliersSanjcak has 40 years’ experienc

VIEW DETAILSRockySea Petro Quick Lock Annular BOPGreatly reduce the time for replacing the ram and effectively improve work efficiency with safety.Compact structure and reduced weight means more operation room.20 years experience in designing and manufacturing QL annular BOP.The working principle and purpose of RockySea Petro QL annular blowout preventers are not fundamentally different from traditional blowout preventers, but their structure has been effectively improved. No need for large high torque bolts, convenie

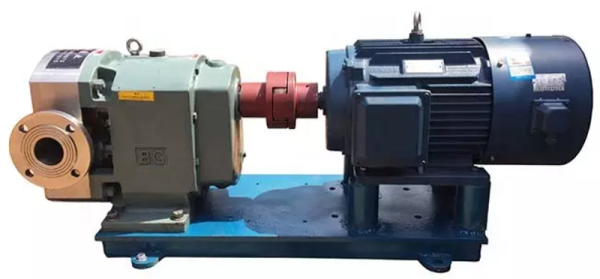

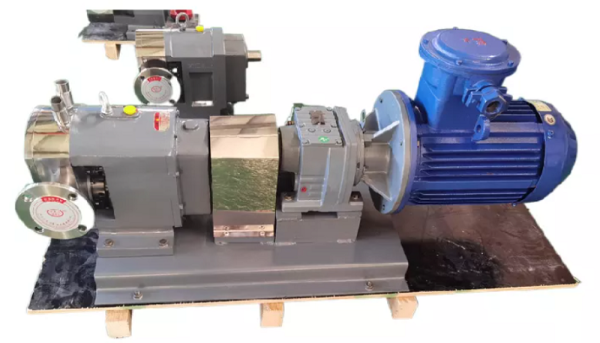

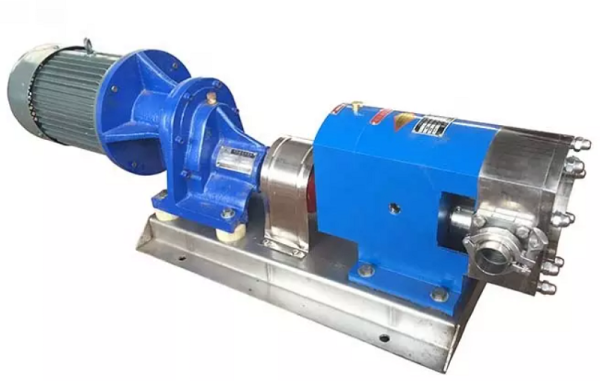

VIEW DETAILSRockySea Petro Rotator Metering Pump

Advantage and feature

Sabjack rotator metering pump has the following advantages.

1. External dynamic and static ring mechanical seal is adopted, which can be directly flushed with water, and is resistant to high temperature and high pressure.

2. Reliable rust prevention and non-toxic sealing.

3. Small volume, large flow, high head pressure, suitable for long distance and high resistance quantitative transmission.

4. After the frequency converter is configured, the flow can be adjusted at will and can be used as a general metering pump.

5. The impeller of the pump is separated from the transmission gear, and a certain clearance is guaranteed between the components in the pump chamber, without contact, wear and low noise

6. Compact structure, convenient maintenance, almost no wearing parts, low operation cost.

7. The streamline structure of the rotor and the rotor chamber are free of dead points and scrap metal parts, which avoid pollution to the transported substances, and are especially suitable for high viscosity media during transportation.

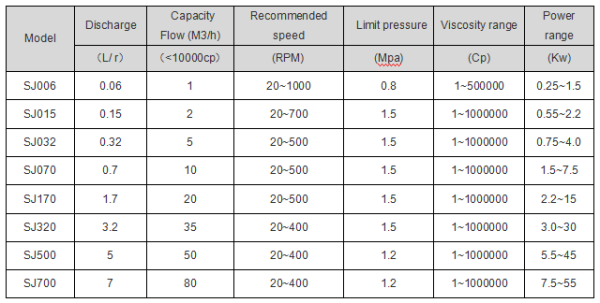

Parameter

RockySea Petro rotator metering pumps have various types to choose.

Operation process

The rotator metering pump is driven by a pair of external synchronous gear boxes The rotor rotates synchronously in the opposite direction driven by the transmission shaft, thus forming a high vacuum degree and discharge pressure. The two rotors divide the rotor chamber into several small spaces and operate in the order of I → II → III → IV. When operating to position I, only the inlet is full of medium; When operating to position II, part of the medium is sealed in chamber II; At position III, the medium is also enclosed in chamber III; When reaching position IV, the two rotors conjugate displacement, the volume at the outlet shrinks, and the medium in the closed area is transported to the outlet pipe. According to this cycle, the medium is continuously transported out.

Description

The rotator metering pump is also called rotor metering pump,roots pump, colloid pump, high consistency slurry pump, etc. The rotor pump is a rotary positive displacement pump, which changes the working volume through the relative movement between the rotor and the pump body, thus increasing the energy of the fluid. ShengjiPetro can produce rotator metering pump according to API 676 standard.

RockySea Petro Copyright © 2008-2025 Inc. SITEMAP