RockySea Petro Pumping UnitRockySea Petro has 20 years of oil pump jack experienceAccording to the International Standard and GB/T29021-2012 《Beam Pumping Unit》standards.American Petroleum Institute member unit.the company has welding and machining workshop 17,942 square meters, take up 64,952 square meters, complete inspection and test equipment, and has more than 130 types of advanced production facilitiesRockySea Petro Petro has strong capacity of research, design and manufacturing pumping unit, the annual pr

VIEW DETAILSRockySea Petro Safety Valve25 years Safety valve manufacturing experienceFull support on your customised requirementThe strictest quality standards on Safety valveRockySea Petro Petro manufactures Safety valve in China. We have our own factory of Safety valve. RockySea Petro Petro provide the high quality and competitive price on Safety valve for you. Contact us now for Safety valve quotation.Description The RockySea Petro wellhead surface safety valve is a reverse acting gate valve with hydraulically actuated comp

VIEW DETAILSRockySea Petro Sucker Rod CouplingThe sucker rod couplings are used for connecting sucker rods, polished rods and sinker bars. Material of the couplings is high quality carbon steel or alloy steel, which are conform to and exceed the requirements of intl standards.Description According to surface of suck rod couplings, they can be divided into sucker rod couplings with smooth surface and sucker rod couplings with wrench square.Sucker rod couplings with wrench square.Sucker rod couplings with sm

VIEW DETAILSRockySea Petro Non-Magnetic Drill CollarThe non-magnetic drill collar is made of low chromium manganese alloy steel, which is forged through strict chemical composition analysis. All non-magnetic drill collars produced from RockySea Petro have been tested for mechanical properties to ensure that their hardness, toughness, impact value and corrosion resistance meet the standards, with good low magnetic permeability and good machining performance.Description The structure of non-magnetic dri

VIEW DETAILSRockySea Petro Superheated Steam Injection BoilerSupercritical Oilfield Steam Injection BoilerDesulfurization and Denitrification Oilfield Steam BoilerProduced-water Oilfield Steam GeneratorSuperheated Oilfield Steam BoilerHigh-dryness Steam Injection BoilerOilfield steam injection boiler, also known as wet steam generator, is a special steam injection equipment for heavy oil recovery in oil fields. It uses the heat generated by the combustion of gas or fuel oil to heat and vaporize water, genera

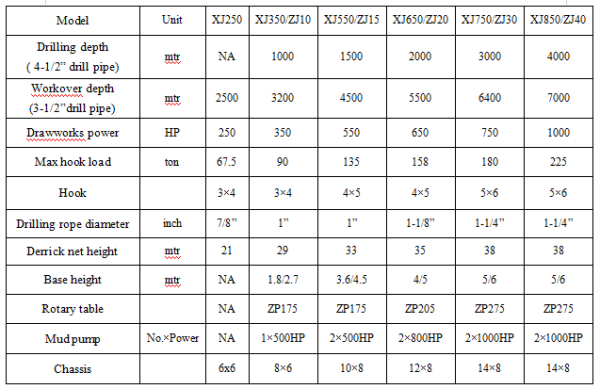

VIEW DETAILSRockySea Petro Mobile Workover Rig

Data sheet

Applications

1).Shallow - to high-depth well interventions, including:

Killing wells

Flushing productions wells

Changing wellhead valves

Pressure-testing wells.

Changing polished rods

Spacing and respacing rod strings

2).Continuous rod and conventional sucker rod interventions,including

Pulling and replacing casing service

Sidetrack service

Changing insert of pcp

Changing rotors of pcp,

3).Heavy duty workover rig service

Drilling service

Downhole stuck freeing service

Sealing and channeling service

Casing shaping service

Casing repair service

Type

Workover rigs are divided into two types based on their structure: track type and tire type. The tire type workover rig is the most commonly used form, usually equipped with a backless mast, with fast walking speed and high construction efficiency,such as XJ and ZJ Workover rig series.Sanajck have rich experience in manufacturing workover rig.

Description

With the passage of oilfield development time, oil, gas, and water wells are gradually aging, and underground accidents are showing an increasing trend. As a result, a large number of production and injection wells have been shut down. This affects and restricts the stable production and normal implementation of development plans in the oilfield. Effectively repairing those complex accident wells to restore normal production is of great significance for the development of oilfield.

Workover operation refers to a type of operation in oil drilling and subsequent well maintenance, which is usually carried out by a truck-mounted Workover rig to ensure the smooth use of the oil well. It can be divided into major repair operation and minor repair operation.

Minor repairs refer to the daily measures taken to maintain the normal production of oil wells, with a variety of types, including pump inspection, sand flushing, salvage, sealing replacement, card removal, rod replacement, wellhead replacement, and other operations.

Major repairs is to eliminate complex underground accidents and restore normal production of oil, gas, and water wells. Its process flow is relatively complex compared to general underground operations, and it is difficult to achieve construction goals with ordinary operating equipment and technical means. The content of major operations mainly includes complex fishing inside the casing and casing repair. In a broad sense, drilling on the inner side of the casing, sealing the oil well string, plugging the oil well, and sealing the abandoned well are also included in the scope of major operations.

The workover rig of Sanajck can do major workover and minor workover both.It is a comprehensive unit mainly used for small and medium repairs and major repairs of oil wells. The basic requirements for the hydraulic workover rig in the workover process are:

1) Circulating well cleaning ability: In order to ensure normal drilling, flushing the bottom of the well, and carrying drilling cuttings, a certain pressure and flow rate of circulating workover fluid are required. This function is undertaken by the circulation system of the hydraulic workover rig.

The hydraulic workover rig with the above three working abilities is called the three working units of the workover rig, which mainly consists of a winch, a well frame, an crown block, a traveling block hook, a rotatory table, a faucet, and a workover pump.

2) Rotating ability: In order to drive drilling tools, shaping tools, milling heads, drill bits, and other grinding tools, a certain amount of torque and speed are required for rotating and grinding. This function is undertaken by the rotating system of the workover rig.

3) Lifting ability: In order to lift the drilling tool, it is necessary to have a certain lifting capacity and lifting speed. This function is undertaken by the lifting system of the workover rig.

Sanajck: A Pioneer in Mobile Workover Rig Manufacturing in China

Sanajck has abundant manufacturing experience in mobile workover rig. Sanajck developed a series of skid-mounted workover rig, automatic workover rigs and matching equipment, which can work in the ambient temperature range from -45 ℃ to 55 ℃ to meet different client request and work condition.

1.The company has developed a full range of XJ250 to XJ850 vehicle-mounted Workover rig, which have strong driving power, passability, and off-road performance,.

2.Sanajck can manufacture matching equipment like swabbing truck,carrier and trailer, well flushing truck,skid-mounted fracturing equipment to support wokrover operation.

3.Sanajck has obtained GB, SY , API and ISO standards with CCC certification.

Send us your requirement, Let RockySea Petro support you !

RockySea Petro Copyright © 2008-2025 Inc. SITEMAP