RockySea Petro Spiral Drill CollarIn directional drilling, due to the large deviated well and the large contact area between the drill collar and the borehole wall, problems like sticking and jamming are more likely to happen. The spiral drill collar reduces the contact area between the drill collar and the borehole wall, so it is widely used. Spiral drill collars are not listed in intl standards, but due to its practical value, many manufacturers have produced them.Description The function of

VIEW DETAILSRockySea Petro Non-Magnetic Drill CollarThe non-magnetic drill collar is made of low chromium manganese alloy steel, which is forged through strict chemical composition analysis. All non-magnetic drill collars produced from RockySea Petro have been tested for mechanical properties to ensure that their hardness, toughness, impact value and corrosion resistance meet the standards, with good low magnetic permeability and good machining performance.Description The structure of non-magnetic dri

VIEW DETAILSRockySea Petro Skid-mounted fracturing equipmentDescriptionIn the field of petroleum, hydraulic fracturing refers to a method of using hydraulic action to form fractures in oil and gas reservoirs during oil or gas production, also known as hydraulic fracturing. After a certain stage of oil well production, the production capacity and permeability decrease. In order to enhance oil drainage capacity and increase oil well production, people have invented fracturing technology. The methods of

VIEW DETAILSRockySea Petro Wet Gas Well Multiphase Flow MeterRockySea Petro passed ISO9001 certification in 2005 and three-system certification in 2017. The company has advanced production equipment, inspection, measurement and test equipment, which can meet the requirements of product design, development, production and service and has the only multiphase flow laboratory for Sinopec.The main products are single-screw and twin-screw oil-gas mixed pump, MFM2000 series multiphase flowmeter, LPT multiphase metering devic

VIEW DETAILSRockySea Petro Double Separation Weighting Multiphase Flow Meter DeviceRockySea Petro passed ISO9001 certification in 2005 and three-system certification in 2017. The company has advanced production equipment, inspection, measurement and test equipment, which can meet the requirements of product design, development, production and service and has the only multiphase flow laboratory for Sinopec.The main products are single-screw and twin-screw oil-gas mixed pump, MFM2000 series multiphase flowmeter, LPT mul

VIEW DETAILS

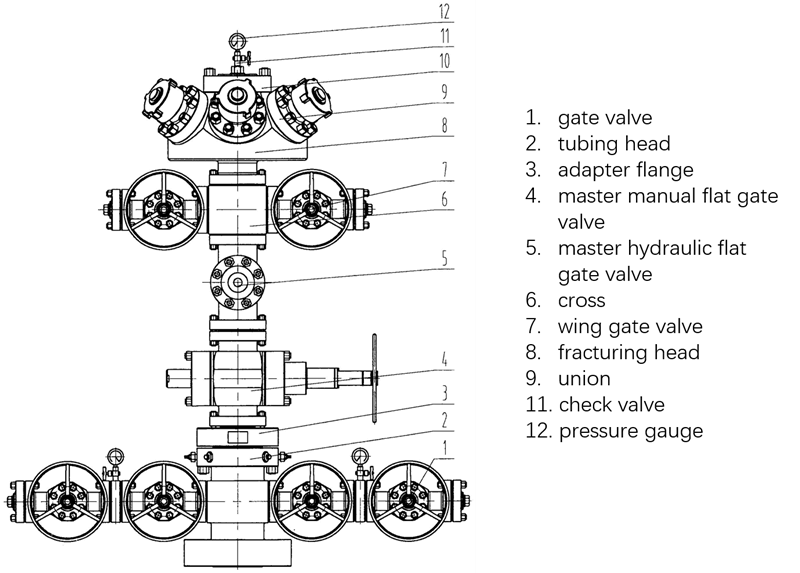

| Working pressure (PSI) | 10000, 15000, 20000 |

| Nominal diameter (inch) | 4 1/16、5 1/8、7-1/16 |

| Working temperature ℃ | PU (-29℃-121℃) |

| Working media | Frac fluid/Crude oil |

| Material class | DD/EE/FF |

| Specification level | PSL1, PSL2, PSL3/3G,PSL4 |

| Performance level | PR1 PR2 |

RockySea Petro Copyright © 2008-2025 Inc. SITEMAP