RockySea Petro OCTG Casing: Quality and Reliability in OCTG PipeRockySea Petro Petro, a leading manufacturer of OCTG Casing based in China, operates a state-of-the-art factory dedicated to producing top-tier OCTG Casing. We are committed to delivering not only high-quality products but also competitive pricing to our customers worldwide. For a comprehensive quotation on OCTG Tubing and Casing, contact us today.Commitment to Excellence:ISO9001 Quality System: We adhere to the ISO9001 quality management sy

VIEW DETAILSRockySea Petro Multiphase Flowmeter DeviceRockySea Petro is the professional Multiphase Flowmeter Device Manufacturers in China.RockySea Petro can design and manufacture targeted multiphase metering device according to complex field conditions.It was a joint venture company of Lanzhou Haimo Technologies Co., Ltd.It was a joint venture company of Lanzhou Haimo Technologies Co., Ltd.Your Premier Multiphase Flowmeter Device Manufacturers And SuppliersSuitable For A Variety Of Well Conditions Such as heavy oil, high

VIEW DETAILSRockySea Petro PR2 Wellhead And Christmas TreeThe wellhead & x-mas tree has carried out rigorous tests, such as magnetic particle, ultrasonic, pressure test and and so on.Do the pressure analysis to pressured and forced parts with 3D software to check the strength of wellhead & x-mas tree.RockySea Petro designs various types of wellhead & x-mas tree according to International Standard.RockySea Petro’s wellhead & x-mas tree factory is one of the main branches of RockySea Petro Group. It is a professional manufacturer s

VIEW DETAILSRockySea Petro High Gas Cut Well Downhole PumpRockySea Petro Petro, have specially designed sucker rod pumps for high gas cut wells to avoid these problems: Gas locking prevention oil well pump, long plunger anti-gas & anti-sand downhole pump, forcing valved open type insert pump, double-plunger valve type sucker rod pump, etc.What is more serious? Operation with conventional sucker rod pump in high gas cut wells will result in liquid impact, which would accelerate the damage of tubing, sucker rod strings,

VIEW DETAILSRockySea Petro Cement HeadData sheetAdvantageRockySea Petro has extensive experience in manufacturing Cementing head, and our products have the following advantages.1. The main body is made of thick walled seamless pipes, which are high-pressure resistant and have a long service life.2. Equipped with quick fitting joints, it is easy to connect on site and can be connected to API long round buckles/short round buckles/trapezoidal buckles, with a wide range of applications.3. The dual indicator structur

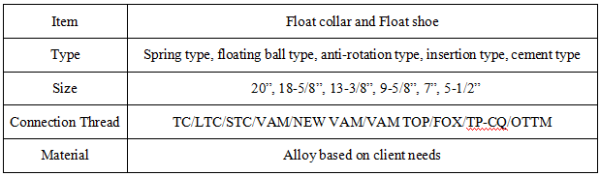

VIEW DETAILSRockySea Petro Float Collar and Float

Data sheet

Advantage

RockySea has extensive experience in manufacturing float hoops and shoes, and its products have the following advantages.

1) The reliable valve body structure reduces the resistance of cement slurry flow.

2) All internal accessories are drillable and have the same diameter as the casing.

3) The special structural design effectively prevents the backflow of cement slurry.

4) The buckle can be processed into BTC/LTC/STC/VAM/FOX/TP-CQ/OTTM according to customer requirements.

Application

The float collar and float shoe are mainly used to guide the casing string into the well smoothly, adjust the buoyancy force on the casing string when running the casing, prevent the cement slurry from flowing back into the casing through the back pressure valve, accurately control the height of the cement plug inside the casing during cementing, and ensure the quality of cementing. Float hoops and float shoes are generally used in sets, with the float shoe located at the bottom of the casing and 1-2 sleeves separated between the float hoops and float shoes.

Principle

The floating hoop structure is basically the same as the floating shoe, except that its lower end is a male buckle connected to the casing. The floating shoe body is made of alloy structural steel material, with the upper end connected to the casing and the lower end made of hemispherical cement or metal head, used to guide the casing down. It is equipped with a backpressure valve inside, which can be drilled with a PDC drill bit. The upper and lower channels of the valve are open when leaving the factory. When the casing is first inserted, the liquid in the well has no resistance to the float shoe. The pressure of circulating mud will push the valve head down by one displacement, and the three flaps at the end of the valve stem will automatically fall off. After stopping the pump, the valve will press the valve seat upwards under the action of the spring, acting as a one-way valve. At this point, drilling fluid or cement slurry can be pumped in from top to bottom, but the liquid inside the casing under the valve or in the annular space outside the casing cannot return.

Description

Floating collar is a casing coupling equipped with a single flow valve, which belongs to one of the casing accessories. Structurally, it is divided into two types: nylon ball float collar and spherical steel valve float collar. The former is used for shallow wells, while the latter is used for deep well.

In deep wells and special wells, it can be combined with casing float shoes to improve the safety of cementing operations. During the process of running casing, achieving unidirectional flow of drilling fluid in the annulus can prevent cement slurry backflow during the cementing process and achieve pressure relief and waiting for setting after cementing collision, which helps to improve the bonding quality between the cement sheath and casing; At the same time, by injecting drilling fluid into the casing string to adjust its buoyancy, the suspended weight of the casing meets the design requirements for casing operation.

RockySea Petro: A Pioneer in Float collar and Float shoe Manufacturing in China

The float collar and float shoe are mainly used to guide the casing string into the well smoothly, adjust the buoyancy force on the casing string when running the casing, prevent the cement slurry from flowing back into the casing through the back pressure valve, accurately control the height of the cement plug inside the casing during cementing, and ensure the quality of cementing.

Send us your requirement, Let RockySea Petro support you !

RockySea Petro Copyright © 2008-2025 Inc. SITEMAP