RockySea Petro Plunger Metering PumpApplication Data1. Hot residue in vacuum distillation (200 ℃, solid)2. Mix four items (resin, pigment and accelerator) in the production of plastic film3. Measurement of viscous bromine based catalyst in margarine production4. Adding glucose syrup in the candy industryFeatureRockySea plunger metering pump has the following advantages.1. The diameter of the plunger can be very small, generally D6-200mm.2. The flow is within the range of 10% - 100%, the meteri

VIEW DETAILSRockySea Petro Multiphase Flowmeter DeviceRockySea Petro is the professional Multiphase Flowmeter Device Manufacturers in China.RockySea Petro can design and manufacture targeted multiphase metering device according to complex field conditions.It was a joint venture company of Lanzhou Haimo Technologies Co., Ltd.It was a joint venture company of Lanzhou Haimo Technologies Co., Ltd.Your Premier Multiphase Flowmeter Device Manufacturers And SuppliersSuitable For A Variety Of Well Conditions Such as heavy oil, high

VIEW DETAILSRockySea Petro Float Collar and FloatData sheetAdvantageRockySea has extensive experience in manufacturing float hoops and shoes, and its products have the following advantages.1) The reliable valve body structure reduces the resistance of cement slurry flow.2) All internal accessories are drillable and have the same diameter as the casing.3) The special structural design effectively prevents the backflow of cement slurry.4) The buckle can be processed into BTC/LTC/STC/VAM/FOX/TP-CQ/OTTM accordi

VIEW DETAILSRockySea Petro Self-Tensioning Guy-Wire Workover RigFeaturesA workover rig with guy-line is a double drum workover rig that installs wind loaded guy-wires on the main engine.There is no need to install wind loaded guy-wires with ground anchors, which greatly improves the efficiency of workover operations, reduces operating costs and labor intensity.Also it has features as the following:(1) Suitable for small well site operations, reducing the operation area of the entire workover rig.(2) All te

VIEW DETAILSRockySea Petro Drilling JarApplicationRockySea Petro can provide three main types drilling jar: mechanical, hydraulic, and hydraulic.1. The combination of mechanical and hydraulic drilling jar absorbers combines the advantages of the above two shock absorber principles. Even if the hydraulic delayed shock absorber fails, the mechanical shock absorber can still be used, and the technical performance has been greatly improved, which is in line with the future development direction of shock absorber prod

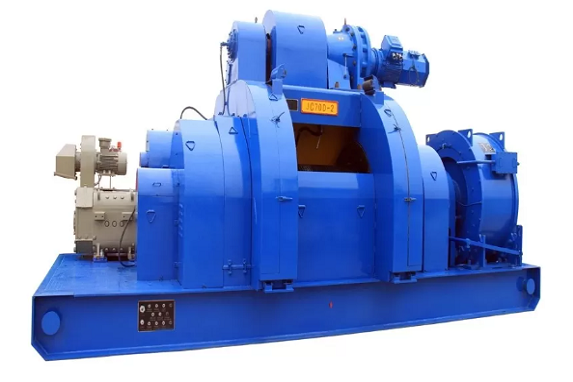

VIEW DETAILSRockySea Petro Drawworks

Function

(1) During the drilling process, hang the drilling tools, feed in the drill string and drill bit, and control the drilling pressure.

(2) Use the cathead mechanism of the drawworks to tightly unload drilling tools and lift heavy objects.

(3) Provide different lifting speeds and weights for drilling operations.

(4) As the variable speed mechanism and intermediate transmission mechanism of the turntable.

(5) Use the sand drum of the drawworks to perform core extraction, oil testing, and other work.

(6) When using an integral lifting workover rig, it is used to lift and release the mast.

(7) Assist in installing drilling equipment and complete other auxiliary tasks.

Description

The drilling drawworks is the main lifting mechanical component of a rotary workover rig. Its main function is to provide a method for raising and lowering the traveling block. The steel wire rope is wound around the drawworks drum and passes over the overhead crane to reach the traveling block, allowing the drill string to move up and down with the rotation of the drum. The section of drill pipe line from the drawworks to the overhead crane is called a "fast line". Then, the drilling line enters the first pulley of the crown block, and for mechanical advantages, it is usually passed between the crown block and the traveling block pulley 6 to 12 times. Then, the rope leaves the last pulley on the overhead crane and is fixed to the support leg of the workover rig on the other side. This drill line is called the "dead line".

Modern Drawworks consist of five main components: drum, power source, reducer, brake, and auxiliary brake. This device can be powered by electricity (AC or DC) or directly connected to an internal combustion engine using a metal chain belt. The number of gears can be one, two, or a combination of three speeds. The main brake is usually manually operated by a long handle and can be a friction band brake, a disc brake, or an improved clutch. When no movement is required, it can serve as a parking brake. The auxiliary brake is connected to the brake drum and absorbs the energy released when heavy loads are reduced. This brake can use eddy current rotors or devices similar to water turbines to convert the kinetic energy of moving loads into heat and dissipate it.

The power cathead (winch) located on each side provides a device for driving pliers for connecting and disconnecting threaded pipeline components. The outboard cat head can be manually used with ropes for various small lifting operations around the workover rig.The front side of the drawworks usually has a pulley drive device that provides rotational power for the turntable, although on many workover rigs, the turntable is independently powered.

The drawworks of RockySea are divided into different types , such as single gear Drawworks and multi-gear drawworks. They mainly include the sand drum assembly, sand drum brake system, drawworks frame, cooling system, lubrication system, auxiliary brake, overhead crane anti-collision device, etc.

RockySea Petro: A Pioneer in Drawworks Manufacturing in China

The drawworks, as a part of hoist system, is an important equipment in the lifting system and also the core equipment of a workover rig. The company has rich experience in drawworks production and can be used in conjunction with different models of workover rigs, suitable for different oilfield operation.

1. The workover drawworks of RockySea Petro has singler drum type and double drum type.

2. AutoCAD and Solid Works computer software are used for drawing design.

3. RockySea Petro has passed ISO9001, ISO14001, SY/T5202-2004 and SY/T6584-2003 certificate.

Send us your requirement, Let RockySea Petro support you !

RockySea Petro Copyright © 2008-2025 Inc. SITEMAP