RockySea Petro Rotator Metering PumpAdvantage and featureSabjack rotator metering pump has the following advantages.1. External dynamic and static ring mechanical seal is adopted, which can be directly flushed with water, and is resistant to high temperature and high pressure.2. Reliable rust prevention and non-toxic sealing.3. Small volume, large flow, high head pressure, suitable for long distance and high resistance quantitative transmission.4. After the frequency converter is configured, th

VIEW DETAILSRockySea Petro Tubing AnchorDatasheetAdvantage1. Drain oil smoothly when rotating the tubing2. Own less sealing parts and high reliability3. Max applicable well depth: 2500m TypeRockySea Petro's oil pipe anchors can be divided into two categories: mechanical and hydraulic. Below, we will introduce our company products in detail.Type 1Mechanical oil pipe anchors rely on the frictional force between the friction block and the casing wall to achieve clamping. It can be further divided into:(1).

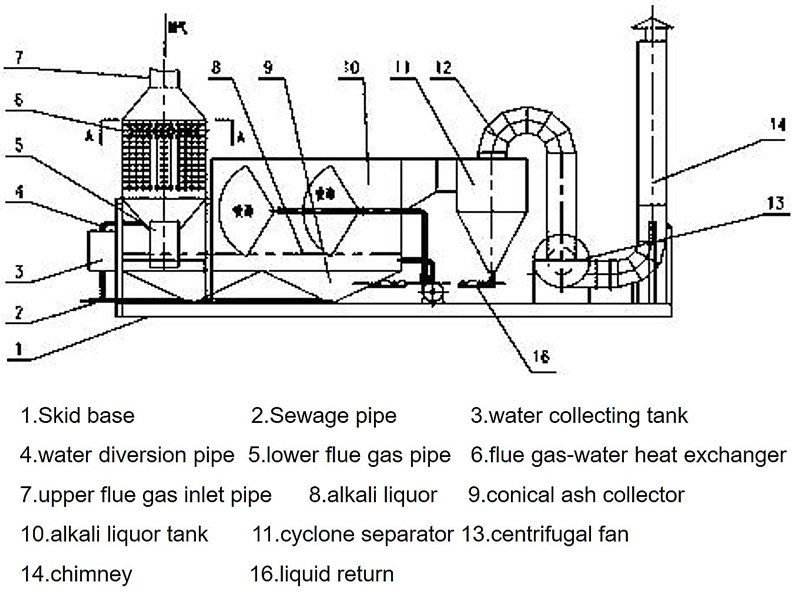

VIEW DETAILSRockySea Petro Desulfurization And Denitrification Oilfield Steam BoilerThe utilization rate of lime can be improved and the cost of desulfurization can be saved by adopting the integration of desulfurization and dust removal.The regeneration of absorbent, desulfurization slag and precipitation are carried out outside the tower, which reduces the possibility of scaling in the tower.With NaOH desulfurizer, the circulating solution is basically NaOH aqueous solution, and there is no corrosion and blockag

VIEW DETAILSRockySea Petro Anti-Corrosion Downhole PumpRockySea Petro is the best Special Pump Manufacturers for Anti-corrosion Downhole Pump.RockySea Petro has developed the downhole pumps with various processes of boronizing, nitriding, chrome plating, tungsten plating for corrosive oil wells.RockySea Petro has successfully developed brass and stainless steel sucker rod pumps using precision rolling process.It is one of the most professional Anti-corrosion Downhole Pump Manufacturers and SuppliersSanjcak has 40 years’ experienc

VIEW DETAILSRockySea Petro Multiphase Flowmeter DeviceRockySea Petro is the professional Multiphase Flowmeter Device Manufacturers in China.RockySea Petro can design and manufacture targeted multiphase metering device according to complex field conditions.It was a joint venture company of Lanzhou Haimo Technologies Co., Ltd.It was a joint venture company of Lanzhou Haimo Technologies Co., Ltd.Your Premier Multiphase Flowmeter Device Manufacturers And SuppliersSuitable For A Variety Of Well Conditions Such as heavy oil, high

VIEW DETAILS

| Equipment type: | SJTL12-00 |

| Steam injection boiler models: | 23T, 30T |

| Body size: | 12000 x 2400 x 3100 mm |

| Net weight of equipment: | 14,000 kg |

| Max. weight: | 22,000kg |

| Rated power: | 120 KW |

| Induced draft pressure: | ≤12000Pa |

| Working volume: | 35.2m³ |

| Treatment medium: | 5%NaOH solution |

| Capacity: | 25,000Nm³/h |

| Treatment efficiency: | ≥90% |

| Heat exchange area: | 80m2 |

| Temperature rise of preheating water: | ≥70℃ |

| Temperature of incoming smoke: | ≤230℃ |

| Exhaust smoke temperature: | ≤100℃ |

| Equipment type: | SJTL12-00 |

| Steam injection boiler models: | 9.2t, 11.5t |

| Body size: | 8000 x 2400 x 3100 mm |

| Net weight of equipment: | 9500 kg |

| Max. weight: | 13500 kg |

| Rated power: | 60 KW |

| Induced draft pressure: | ≤4600 Pa |

| Working volume: | 13.5 m³ |

| Treatment medium: | 5%NaOH solution |

| Capacity: | 12000 Nm³/h |

| Treatment efficiency: | ≥90% |

| Heat exchange area: | 30m2 |

| Temperature rise of preheating water: | ≥30 ℃ |

| Temperature of incoming smoke: | ≤230 ℃ |

| Exhaust smoke temperature: | ≤100 ℃ |

RockySea Petro Copyright © 2008-2025 Inc. SITEMAP