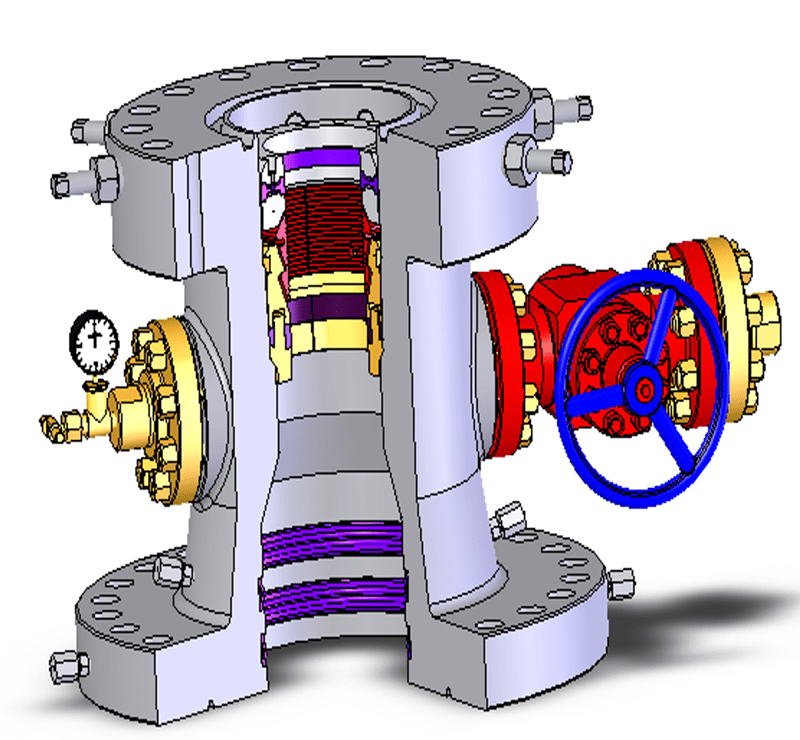

RockySea Petro Cameron U And C Ram BOPAll BOP will receive rigorous tests, such as magnetic particle, ultrasonic, pressure test and so on.AutoCAD and Solid Works computer software are used for drawing design. Also virtual prototype technology is used for simulation and verification of strength.RockySea Petro has been certified by ISO9001, ISO 14001 standard.RockySea Petro Petro owns a strong ability about research, design and manufacture, of Blowout preventer. The company can supply Cameron U and C ram BOP which

VIEW DETAILSRockySea Petro Kelly BarRockySea Petro has abundant experience in R & D, production and sales of Kelly bars. The Kelly bar is located at the top of the drill string, and its main function is to transmit torque and bear the total amount of the drill string. The end face of the driving part of Kelly is divided into square and regular hexagon, which are most used in oil drilling Kelly is about three times thicker than drill pipe and made of high strength alloy steel, so it has high tensile strength and t

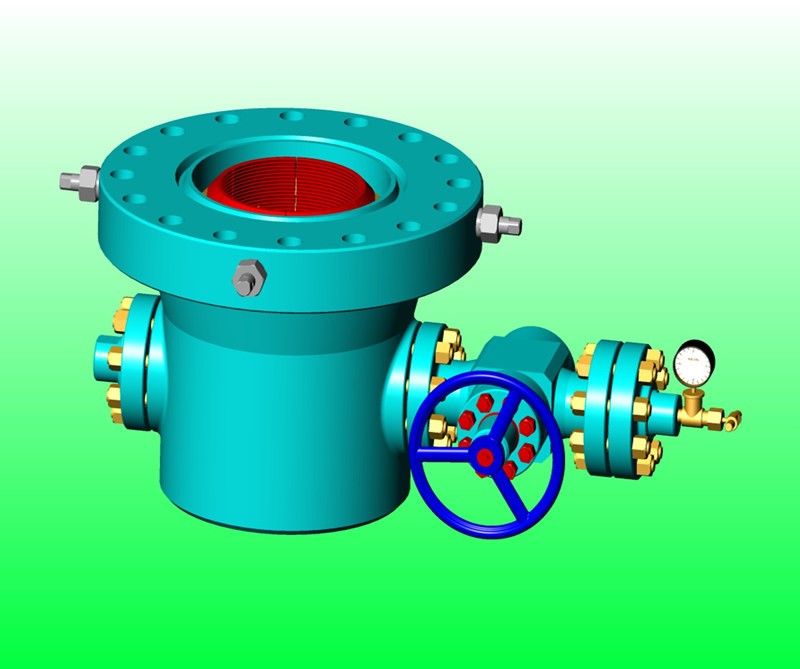

VIEW DETAILSRockySea Petro Gas Recovery Wellhead And X-Mas TreeSuperior gas tight performance and pressure/corrosion proof performance.The sealing surface is very hard and fits accurately.Metal spray valve gate and seat.Excellent sealing performance and small rotating torque.Special structures composite stem seal.RockySea Petro has more than 40 years of experience in wellhead and christmas tree production, with advanced manufacturing and testing equipment, can produce a variety of pressure levels, material levels, spe

VIEW DETAILSRockySea Petro Rod PumpThe raw material of rod pump parts should be inspected after heat treatment, the mechanical properties, chemical compositions and metallographic structures must be inspected by batch. The rod pump parts should be inspected several times during the processing procedure. Some key points like the outer diameter of the plunger and the inner diameter of the pump barrel should be 100% inspected.Your Best Pump ManufacturersSealing performance tests must be carried out 100% after fini

VIEW DETAILSRockySea Petro Choke ValveThe strictest quality standards on Choke valve25 years Choke valve manufacturing experienceFull support on your customised requirementRockySea Petro Petro manufactures Choke valve in China. We have our own factory of Choke valve. RockySea Petro Petro provide the high quality and competitive price on Choke valve for you. Contact us now for Choke valve quotation.Description The choke valve is a type of control valve which is designed to accurately control the flow rate of the wellhead

VIEW DETAILS

| Model Parameter | KY65-21, KY65-35, KY80-21/35 |

| Working pressure (PSI) | 2000, 3000, 5000 |

| Nominal diameter (inch) | 2-9/16,3-1/8 |

| Top flange of tubing head | 7-1/16“~13-5/8” |

| Bottom flange of tubing head | 7-1/16“~13-5/8” |

| Working temperature ℃ | -29℃-121℃ |

| Working media | Crude oil |

| Material class | BB/CC/DD/EE/FF |

| Specification level | PSL1,PSL2,PSL3 |

| Performance level | PR1 |

1 Casing Spools

C-22 casing spools feature a versatile straight bore design that can accept a wide variety of slip and mandrel type casing hangers.

Features a 45° landing shoulder capable of supporting maximum casing loads.

Prevents test plugs from wedging under pressure.

Line Pipe Outlets.

Studded Side Outlets.

C-21 and C-22 slip-type casing hangers.

Mandrel style casing hangers.

Additional sizes available upon request.

Available in C-29 profile (Available upon request).

C-22-BP casing spools are supplied with (2) lock screws for wear bushing retention.

C-22-L and C-29-L casing spools are supplied with a full set of lock screws for mandrel casing hanger and packoff retention (Available upon request)

PE/BG bottom, for use with PE secondary seal bushing (Standard).

HPE bottom, for use with HPE secondary seal bushing for high pressure applications (Available upon request).

2 Casing Heads

C-22 casing heads feature a versatile straight bore design that can accept a wide variety of slip and mandrel type casing hangers.

Features a 45° landing shoulder capable of supporting maximum loads

Prevents test plugs from wedging under pressure

Line Pipe Outlets

Studded Side Outlets

C-21 and C-22 slip-type casing hangers

Mandrel style casing hangers

Additional sizes available upon request

Available in C-29 profile (Available upon request)

C-22-BP casing heads are supplied with lock screws for wear bushing retention

C-22-L and C-29-L casing heads are supplied with a full set of lock screws for mandrel casing hanger and packoff retention (Available upon request)

Slip-on weld

Slip-on weld with O-ring

Threaded

3 Tubing Spools

Tubing heads feature a versatile straight bore design for single and multiple completions. This design accepts all TC series tubing hangers and easily converts from a single completion to multiple completions with the addition and alignment pin(s). The tubing heads are manufactured in API 6A low alloy steel or stainless steel.

Basic Parameters

Nominal size of top flange (in):

7-1/16 Top flange.

Nominal size of bottom flange (in):

7-1/16, 11, 13-5/8.

Bottom flange working pressure (PSI):

2M, 3M, 5M, 10M, 15M, 20M.

Nominal size of side exit (in):

2-1/16, 2-9/16.

Features a 45° landing shoulder capable of supporting maximum loads.

Line Pipe Outlets

Studded Side Outlets

WTCM tubing heads accept a wide variety of tubing hanger styles including mandrel and wrap-around.

PE/BG bottom, for use with PE secondary seal bushing (Standard).

HPE bottom, for use with HPE secondary seal bushing for high pressure applications (Available upon request).

Additional sizes available upon request.

Available with ET (Integral) style lock screws.

Flanged top Tubing Heads available with slip-on weld or threaded bottoms.

RockySea Petro Copyright © 2008-2025 Inc. SITEMAP