RockySea Petro Deep Well Oil Well PumpWhen the pump barrel is stretched and deformed, the pump plunger will not be running smoothly, and even the barrel may trip or break;The valve may be damaged and invalidThe valve cage may break and fail;RockySea Petro developed a lot of special oil well pumps to solve the above problems, including a suspension pump, bridge-type pump, solid plunger pump, etc.The oil well pump efficiency may be reduced to less than 30%Your Premier Deep Well Oil Well Pump Manufacturers An

VIEW DETAILSRockySea Petro Cement HeadData sheetAdvantageRockySea Petro has extensive experience in manufacturing Cementing head, and our products have the following advantages.1. The main body is made of thick walled seamless pipes, which are high-pressure resistant and have a long service life.2. Equipped with quick fitting joints, it is easy to connect on site and can be connected to API long round buckles/short round buckles/trapezoidal buckles, with a wide range of applications.3. The dual indicator structur

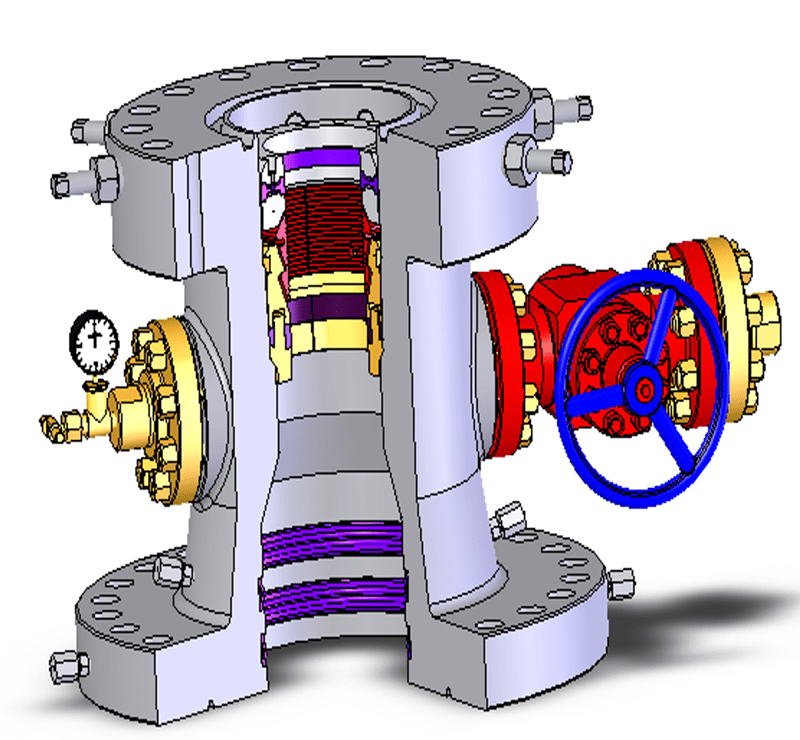

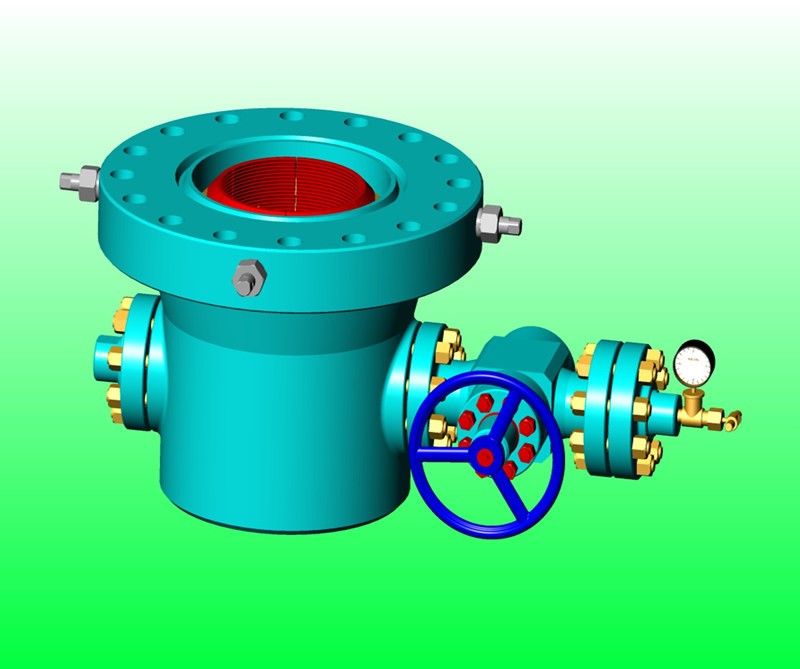

VIEW DETAILSRockySea Petro Coventional Wellhead And Christmas TreeThe wellhead and Christmas tree has carried out rigorous tests, such as magnetic particle, ultrasonic, pressure t est and so on.Do the pressure analysis to pressured and forced parts with 3D software to check the strength of the wellhead and Christmas tree.RockySea Petro’s oil wellhead equipment factory is one of the main branches of RockySea Petro Group. It is a professional manufacturer specializing in the development, design, production, remanufacturing,

VIEW DETAILSRockySea Petro Float Collar and FloatData sheetAdvantageRockySea has extensive experience in manufacturing float hoops and shoes, and its products have the following advantages.1) The reliable valve body structure reduces the resistance of cement slurry flow.2) All internal accessories are drillable and have the same diameter as the casing.3) The special structural design effectively prevents the backflow of cement slurry.4) The buckle can be processed into BTC/LTC/STC/VAM/FOX/TP-CQ/OTTM accordi

VIEW DETAILSRockySea Petro Workover RigWorkover Rig is a specialized piece of equipment used in the oil and gas industry for performing workover operations. Workover operations involve tasks such as well stimulation, well abandonment, and well intervention, which require a rig capable of handling various tools and techniques. The Workover Rig is designed to be robust and versatile, able to handle a wide range of jobs efficiently and safely. It typically consists of a mast, which supports the rig's lif

VIEW DETAILS

| Model Parameter | KY65-21, KY65-35, KY80-21/35 |

| Working pressure (PSI) | 2000, 3000, 5000 |

| Nominal diameter (inch) | 2-9/16,3-1/8 |

| Top flange of tubing head | 7-1/16“~13-5/8” |

| Bottom flange of tubing head | 7-1/16“~13-5/8” |

| Working temperature ℃ | -29℃-121℃ |

| Working media | Crude oil |

| Material class | BB/CC/DD/EE/FF |

| Specification level | PSL1,PSL2,PSL3 |

| Performance level | PR1 |

1 Casing Spools

C-22 casing spools feature a versatile straight bore design that can accept a wide variety of slip and mandrel type casing hangers.

Features a 45° landing shoulder capable of supporting maximum casing loads.

Prevents test plugs from wedging under pressure.

Line Pipe Outlets.

Studded Side Outlets.

C-21 and C-22 slip-type casing hangers.

Mandrel style casing hangers.

Additional sizes available upon request.

Available in C-29 profile (Available upon request).

C-22-BP casing spools are supplied with (2) lock screws for wear bushing retention.

C-22-L and C-29-L casing spools are supplied with a full set of lock screws for mandrel casing hanger and packoff retention (Available upon request)

PE/BG bottom, for use with PE secondary seal bushing (Standard).

HPE bottom, for use with HPE secondary seal bushing for high pressure applications (Available upon request).

2 Casing Heads

C-22 casing heads feature a versatile straight bore design that can accept a wide variety of slip and mandrel type casing hangers.

Features a 45° landing shoulder capable of supporting maximum loads

Prevents test plugs from wedging under pressure

Line Pipe Outlets

Studded Side Outlets

C-21 and C-22 slip-type casing hangers

Mandrel style casing hangers

Additional sizes available upon request

Available in C-29 profile (Available upon request)

C-22-BP casing heads are supplied with lock screws for wear bushing retention

C-22-L and C-29-L casing heads are supplied with a full set of lock screws for mandrel casing hanger and packoff retention (Available upon request)

Slip-on weld

Slip-on weld with O-ring

Threaded

3 Tubing Spools

Tubing heads feature a versatile straight bore design for single and multiple completions. This design accepts all TC series tubing hangers and easily converts from a single completion to multiple completions with the addition and alignment pin(s). The tubing heads are manufactured in API 6A low alloy steel or stainless steel.

Basic Parameters

Nominal size of top flange (in):

7-1/16 Top flange.

Nominal size of bottom flange (in):

7-1/16, 11, 13-5/8.

Bottom flange working pressure (PSI):

2M, 3M, 5M, 10M, 15M, 20M.

Nominal size of side exit (in):

2-1/16, 2-9/16.

Features a 45° landing shoulder capable of supporting maximum loads.

Line Pipe Outlets

Studded Side Outlets

WTCM tubing heads accept a wide variety of tubing hanger styles including mandrel and wrap-around.

PE/BG bottom, for use with PE secondary seal bushing (Standard).

HPE bottom, for use with HPE secondary seal bushing for high pressure applications (Available upon request).

Additional sizes available upon request.

Available with ET (Integral) style lock screws.

Flanged top Tubing Heads available with slip-on weld or threaded bottoms.

RockySea Petro Copyright © 2008-2025 Inc. SITEMAP