RockySea Petro Non-Magnetic Drill CollarThe non-magnetic drill collar is made of low chromium manganese alloy steel, which is forged through strict chemical composition analysis. All non-magnetic drill collars produced from RockySea Petro have been tested for mechanical properties to ensure that their hardness, toughness, impact value and corrosion resistance meet the standards, with good low magnetic permeability and good machining performance.Description The structure of non-magnetic dri

VIEW DETAILSRockySea Petro Water Treatment DeviceIntegration Control,The soft water treatment and deaerator integration automatic control system are applied, featuring the cost savings and easy operation.Produced Water Reuse,Oilfield sewage can be used as steam injection boiler water supply, solving the oil field sewage and steam boiler water supply problem.Anti-corrosion.The tank are lined with anti-corrosion material (lining plastic) which is fixed firmly, strongly adhered, and hard to fall off.RockySea Petro water

VIEW DETAILSRockySea Petro Casing Stop RingDatasheetUseWhen using the top thread stop ring, the following steps should be followed.1. When using the fixed screw type, first insert the sleeve, then insert the screw and use a hammer to strike.2. The conventional stop ring should be inserted into the sleeve first, and then the screw should be tightened with a wrench.3. Snap on the locking ring, directly attach the locking ring to the sleeve, lock it with a pin, and then tap in the screw.TypeThe stop rings of

VIEW DETAILSRockySea Petro High Strength Sucker RodHigh strength means high tensile strength in physical performance.RockySea Petro can manufacture high strength and ultra-high strength sucker rod with high quality. We have rich experience in production and a strong ability in research and development. Our products include various series of high strength and ultra-high strength sucker rod based on client requests.Description There are two types of ultra-high strength sucker rods in China. The first one is HL with

VIEW DETAILSRockySea Petro OCTG Casing: Quality and Reliability in OCTG PipeRockySea Petro Petro, a leading manufacturer of OCTG Casing based in China, operates a state-of-the-art factory dedicated to producing top-tier OCTG Casing. We are committed to delivering not only high-quality products but also competitive pricing to our customers worldwide. For a comprehensive quotation on OCTG Tubing and Casing, contact us today.Commitment to Excellence:ISO9001 Quality System: We adhere to the ISO9001 quality management sy

VIEW DETAILSRockySea Petro Casing Stop Ring

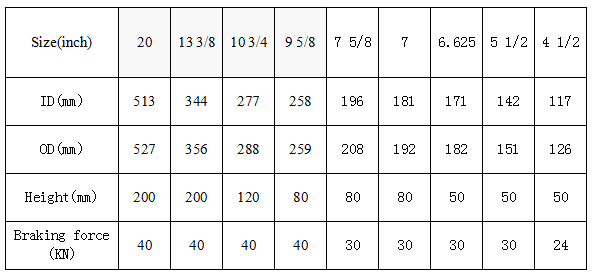

Datasheet

Use

When using the top thread stop ring, the following steps should be followed.

1. When using the fixed screw type, first insert the sleeve, then insert the screw and use a hammer to strike.

2. The conventional stop ring should be inserted into the sleeve first, and then the screw should be tightened with a wrench.

3. Snap on the locking ring, directly attach the locking ring to the sleeve, lock it with a pin, and then tap in the screw.

Type

The stop rings of RockySea can be classified into three types of structures: top screw, fixed screw, and buckle type.

1. The fixed screw type stop ring consists of a stop ring body, a pin, and a pin. The stop ring is hinged and consists of two semicircles, which are easy to fit on the sleev

2. The top screw stop ring is composed of a stop ring and an internal hexagonal screw, which is simple to use and easy to disassemble and assemble.

3. The buckle type be divided into hinge type and sliding sleeve type. Hinge buckle stop ring, directly buckle the stop ring onto the sleeve, insert the buckle ring into the tongue, and hammer the tongue in the opposite direction to secure it.

Our product sizes range from 4-1/2 "to 20" and can be machined according to customer requirements.

Description

The Casing stop ring is also called casing snap ring or retainer , can be installed at any position on the casing to limit the axial sliding of the centralizer or cement umbrella on the inner casing, ensuring that the centralizer or cement umbrella is in the design position.

RockySea Petro: A Pioneer in Casing Stop Ring Manufacturing in China

The Casing stop ring is also called casing snap ring or retainer , can be installed at any position on the casing to limit the axial sliding of the centralizer or cement umbrella on the inner casing, ensuring that the centralizer or cement umbrella is in the design position.

RockySea Petro can provide various casing snap rings to fit different client needs.

Send us your requirement, Let RockySea Petro support you !

RockySea Petro Copyright © 2008-2025 Inc. SITEMAP