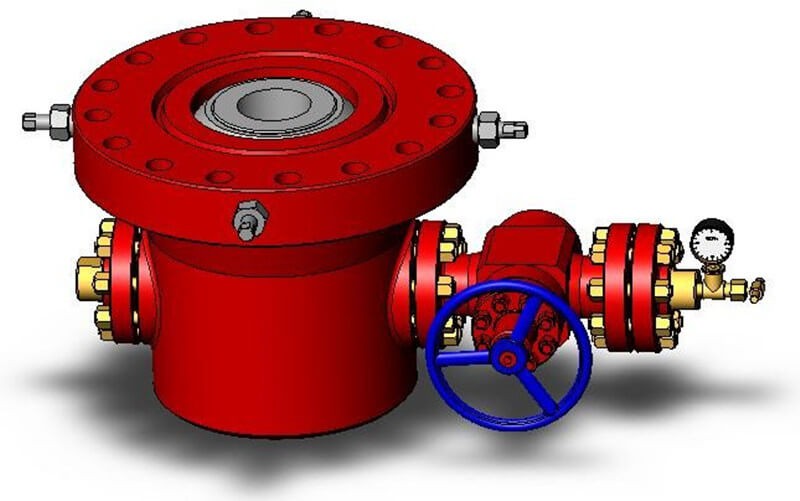

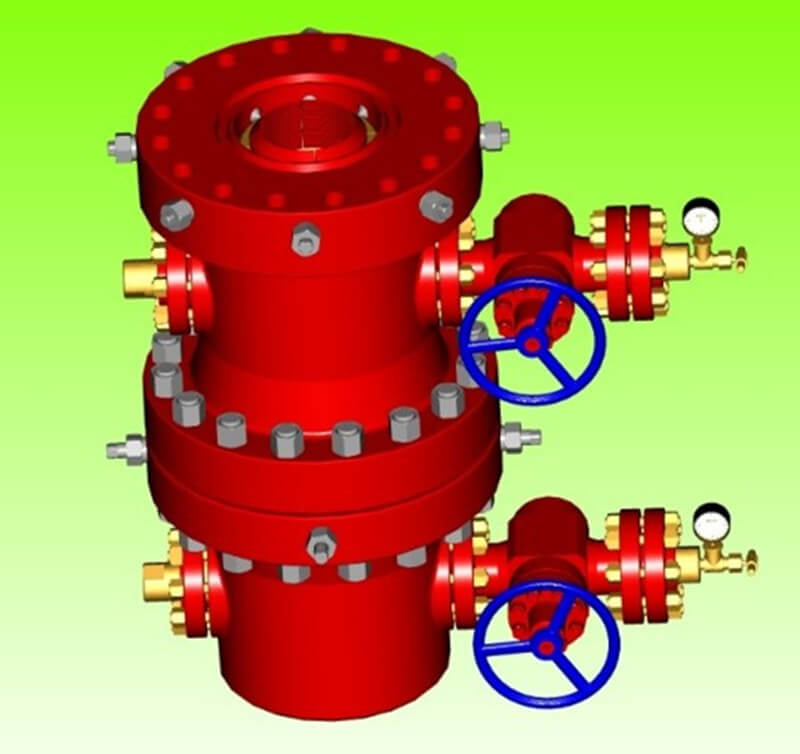

RockySea Petro Frac Wellhead And Christmas TreeIn the process of oil recovery, multistage fracturing of horizontal wells is currently the most advanced technology in the world and represents the development direction of oil and gas production technology. Multistage fracturing technology is to strictly control the number, diameter, and phase of perforation in several or more horizontal sections with better reservoir along the horizontal wellbore, according to the physical properties and the character

VIEW DETAILSRockySea Petro Drilling PipeRockySea Petro has abundant manufacturing experience in OCTG drilling pipes.Exported to the United States, Canada, Europe, Africa and Middle East and all over the world.Our drilling pipes also have various types to fit different environments and applications.The company has passed ISO 9001, and other quality certification systems.RockySea Petro its establishment, RockySea Petro has always insisted on taking the market as the center, taking R & D as the driving force, and const

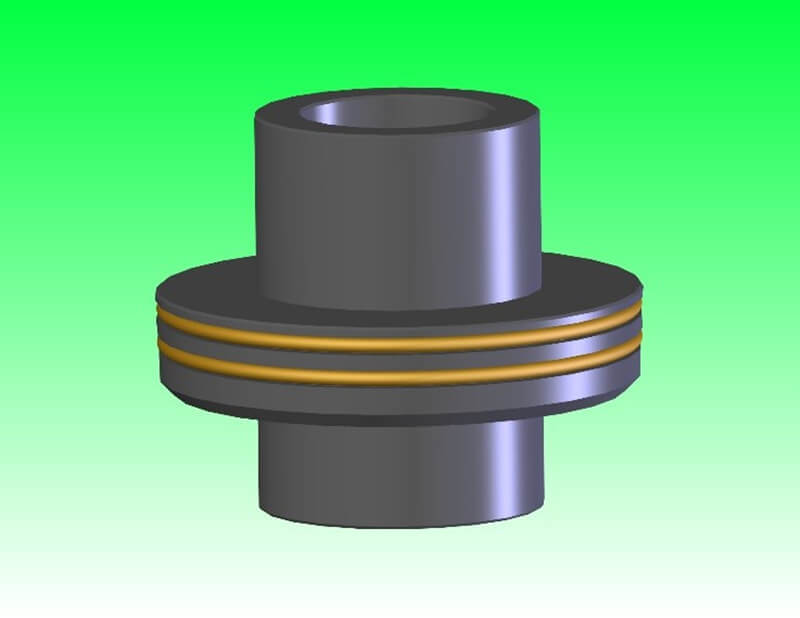

VIEW DETAILSRockySea Petro Rotator Metering PumpAdvantage and featureSabjack rotator metering pump has the following advantages.1. External dynamic and static ring mechanical seal is adopted, which can be directly flushed with water, and is resistant to high temperature and high pressure.2. Reliable rust prevention and non-toxic sealing.3. Small volume, large flow, high head pressure, suitable for long distance and high resistance quantitative transmission.4. After the frequency converter is configured, th

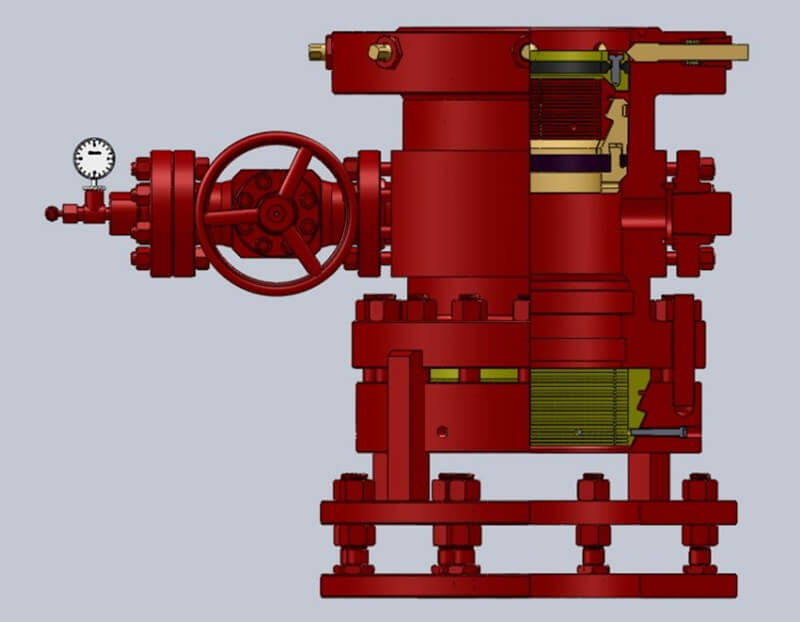

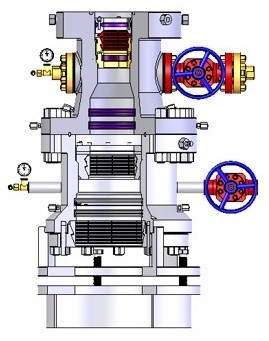

VIEW DETAILSRockySea Petro Skid-mounted fracturing equipmentDescriptionIn the field of petroleum, hydraulic fracturing refers to a method of using hydraulic action to form fractures in oil and gas reservoirs during oil or gas production, also known as hydraulic fracturing. After a certain stage of oil well production, the production capacity and permeability decrease. In order to enhance oil drainage capacity and increase oil well production, people have invented fracturing technology. The methods of

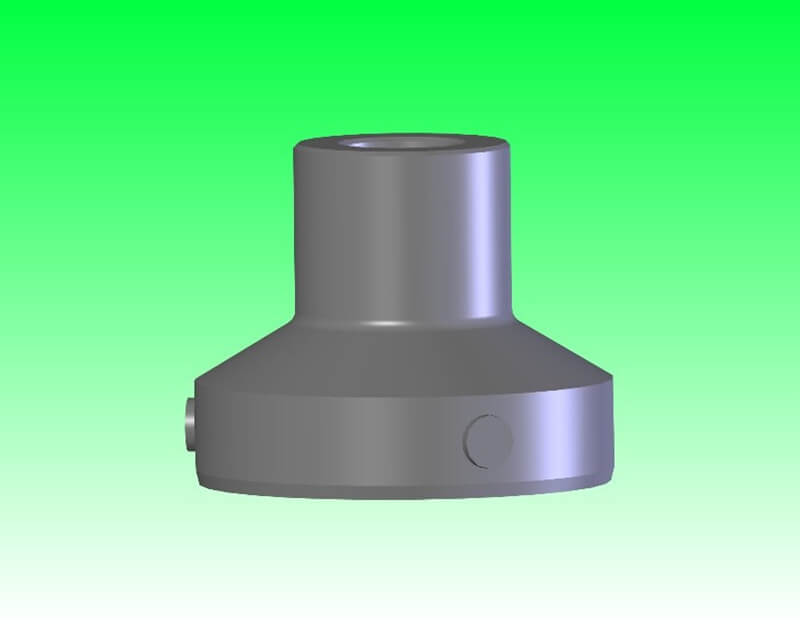

VIEW DETAILSRockySea Petro Choke ValveThe strictest quality standards on Choke valve25 years Choke valve manufacturing experienceFull support on your customised requirementRockySea Petro Petro manufactures Choke valve in China. We have our own factory of Choke valve. RockySea Petro Petro provide the high quality and competitive price on Choke valve for you. Contact us now for Choke valve quotation.Description The choke valve is a type of control valve which is designed to accurately control the flow rate of the wellhead

VIEW DETAILS

Parameters:

| Rated WP | 21MPa、35MPa 、70MPa 、105MPa |

| PSL | PSL1、PSL2、PSL3、PSL3G、PSL4 |

| PR | PR1 |

| TC | P、U、L |

| MC | AA、BB、CC、DD、EE、FF |

| Working pressure (PSI) | 2000, 3000, 5000,10000,15000,20000 |

| Nominal diameter (inch) | 2-1/16、2-9/16、3-1/8、4-1/16 |

| Working temperature ℃ | K,LU ,X,Y(-60℃-370℃) |

| Working media | Oil/Gas |

| Material class | AA/BB/CC/DD/EE/FF/HH |

| Specification level | PSL1/PSL2, PSL3/3G, PSL4 |

| Performance level | PR1 PR2 |

RockySea Petro Copyright © 2008-2025 Inc. SITEMAP