RockySea Petro Downhole Pump FittingsWe establishes cooperative relationships with international customers such as Shell, GE, Schlumberger, and JOHN CRANE.Exported to the United States, Europe, Asia and Asia,The standard parts of the sucker rod pump produced by our company are well-selected, precision-made, stable in quality and excellent in performance, .Your Premier Downhole Pump Fittings Manufacturers And Suppliers.Valve Rods Valve rod materials include steel, alloy steel, stainless steel and bra

VIEW DETAILSRockySea Petro Mobile Workover RigData sheetApplications1).Shallow - to high-depth well interventions, including:Killing wellsFlushing productions wellsChanging wellhead valvesPressure-testing wells.Changing polished rods Spacing and respacing rod strings2).Continuous rod and conventional sucker rod interventions,includingPulling and replacing casing serviceSidetrack serviceChanging insert of pcpChanging rotors of pcp,3).Heavy duty workover rig serviceDrilling serviceDownhole stuck freeing se

VIEW DETAILSRockySea Petro Vortex Separation Multiphase FlowmetersFull support on your customised requirementThe strictest quality standards on Flow Meter Device25 years Flow Meter Device manufacturing experienceRockySea Petro passed ISO9001 certification in 2005 and three-system certification in 2017. The company has advanced production equipment, inspection, measurement and test equipment, which can meet the requirements of product design, development, production and service and has the only multiphase flow laborato

VIEW DETAILSRockySea Petro Low Profile Pumping UnitLow Profile Nodding DonkeyBeam Balanced Pump JackRM Beam Pump(ReversMark Beam Pump)Conventionalpumping unitRockySea Petro Petro has a strong pumping unit design ability. According to International Standard and China national standard, SanJack Petro has designed and developed a series of pumping units according to market demand.Description Low profile pumping unit is designed for applications where pump height is a critical concern. For locations with overhead irr

VIEW DETAILSRockySea Petro Superheated Steam Injection BoilerSupercritical Oilfield Steam Injection BoilerDesulfurization and Denitrification Oilfield Steam BoilerProduced-water Oilfield Steam GeneratorSuperheated Oilfield Steam BoilerHigh-dryness Steam Injection BoilerOilfield steam injection boiler, also known as wet steam generator, is a special steam injection equipment for heavy oil recovery in oil fields. It uses the heat generated by the combustion of gas or fuel oil to heat and vaporize water, genera

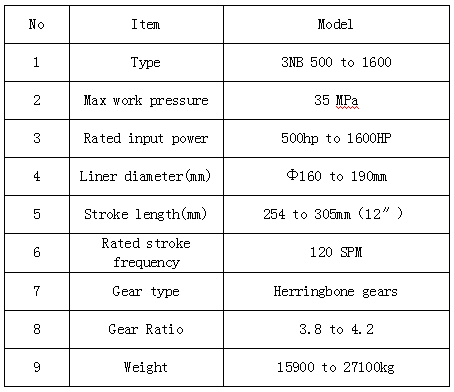

VIEW DETAILSRockySea Petro 3NB Series Mud Pump

Data sheet

Function

1. Remove rock debris from the bottom of the well and send it back to the surface;

2. Handle complex underground situations. When encountering fractured formations, pump in plugging materials, and when encountering stuck drilling, pump in crude oil and diesel to release the stuck.

3. Make mud cakes on the wellbore to prevent collapse;

4. Balance or control the pressure of oil, gas, and water layers in the drilled well section to prevent blowout;

5. Cool the drill bit and lubricate the rotating drill string.

Use and Maintenance

1. Disassemble the valve cover and cylinder head once a week to remove sludge and clean thoroughly. Check the inner sleeve of the valve stem guide. If there is obvious wear and the gap between the valve guide rod and the inner sleeve exceeds 3mm (0.11 "), a new inner sleeve should be replaced. When reinstalling the valve cover and cylinder head, the threaded part should be coated with molybdenum disulfide composite calcium based grease.

2. Check the piston locking nut. If it is corroded or damaged, replace it with a new locking nut. (Note: After disassembling and assembling the nut three times, the sealing ring embedded in it has lost its locking ability.)

3. Check the usage of the valve and valve seat, replace the valve rubber, valve body, and valve seat that are severely worn or punctured (note: both the valve seat and valve body should be replaced at the same time).

4. Drain water from the screw plug on the frame drain hole cover until oil is visible.

Component

The 3NB mud pump mainly consists of two parts: the power end and the hydraulic end. The power end includes: frame assembly, transmission shaft assembly, crankshaft assembly, crosshead assembly, etc; The hydraulic end includes: hydraulic cylinder, valve assembly, cylinder liner, piston assembly, suction pipe, discharge pipe, exhaust air bag, safety valve, spray device, etc.

Design

The drilling pump of RockySea Petro mainly consists of two parts: the power end and the hydraulic end. As shown in Figure 1, the power end is composed of a small gear shaft, a crank connecting rod, and a cross slider mechanism, which provides power to the hydraulic end and transforms rotary motion into linear reciprocating motion. The piston at the hydraulic end uses the power from the power end to move back and forth in the cylinder liner, working together with the suction and discharge valves to compress low-pressure mud and discharge high-pressure mud.

Description

In the operation of using rotary drilling method to drill oil and natural gas wells, the drilling reciprocating pump is used to pump drilling fluid, i.e. mud, to circulate and flush the well. During drilling, the mud pump injects mud into the wellbore along with the drill bit, playing a role in cooling the drill bit, cleaning drilling tools, fixing the wellbore wall, driving drilling, and bringing rock cuttings back to the surface.So drilling pumps are usually referred to as mud pumps, which are the core components of drilling and workover operations.

The 3NB series mud pump are specially developed by RockySea Petro for drilling and workover.

RockySea Petro: A Pioneer in 3NB Series Mud Pump Manufacturing in China

The 3NB mud pump of RockySea Petro is a horizontal three cylinder single acting piston pump, which is an important equipment for drilling operations. During operation, it delivers circulating high-pressure drilling fluid to the bottom of the well, washes the bottom of the well, breaks rocks, cools and lubricates the drill bit, and carries rock cuttings back to the surface. This product is designed, produced, and inspected according to the API Spec 7K standard.

Send us your requirement, Let RockySea Petro support you !

RockySea Petro Copyright © 2008-2025 Inc. SITEMAP